Product Description

Overview

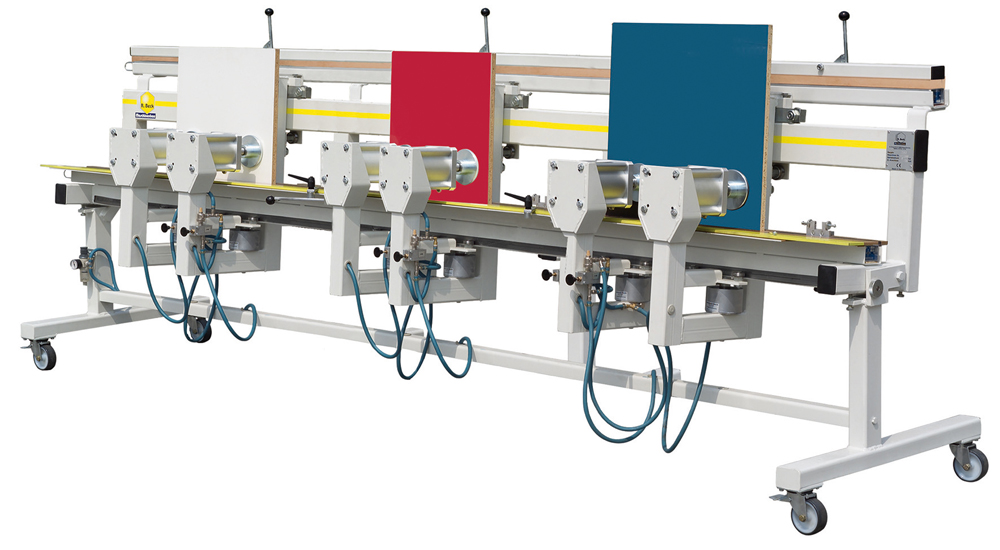

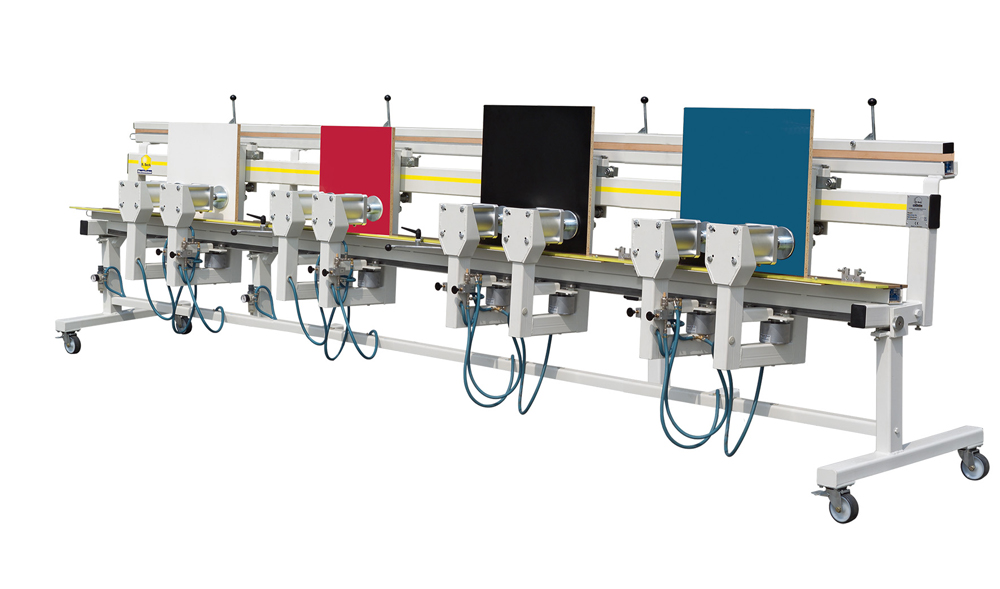

The Hoffmann MOBIL 2500, 3000 and 3600 series edgebanding presses are designed to quickly and precisely attach solid wood edges to panels made of common sheet goods such as MDF, particleboard, plywood, etc.

We offer three different models to meet any production need.

Hoffman MOBIL 2500 - 8 foot working length - two clamping stations

Hoffmann MOBIL 3000 - 10 foot working length - three clamping stations

Hoffmann MOBIL 3600 - 12 foot working length - four clamping stations

Comparison between HOFFMANN MOBIL 2500, 3000 and 3600 series edgebanding press models

|

Technical Specifications MOBIL Press 2500 MOBIL PRESS 3000 MOBIL PRESS 3600 |

|||

|

Power Supply |

230 Volts, Single Phase, 1.5kW |

230 Volts, Single Phase, 1.5kW |

230 Volts, Single Phase, 1.5kW |

|

Compressed Air |

90 PSI - 6 BAR |

90 PSI - 6 BAR |

90 PSI - 6 BAR |

|

Max. Edgeband Size |

98"(L) x 4"(W) x 2"(D) |

118"(L) x 4"(W) x 2"(D) |

142"(L) x 4"(W) x 2"(D) |

|

Heating Elements |

1 x pre-heater 1 x main element |

1 x pre-heater 1 x main element |

1 x pre-heater 1 x main element |

|

Clamp Cylinders |

4 (2 pair) |

6 (3 pair) |

8 (4 pair) |

|

Individual Clamp Controls |

2 |

3 |

4 |

|

Adjustable Miter Stop |

Included |

Included |

Included |

|

Dimensions |

106"(L) x 48"(W) x 34"(H) |

126"(L) x 48"(W) x 34"(H) |

150"(L) x 48"(W) x 34"(H) |

|

Approx. Weight |

880 Lbs. |

1,100 Lbs. |

1,320 Lbs. |

|

Order Number |

BE2500100 |

BE3000100 |

BE3600100 |

A little History

The HOFFMANN MOBIL 2500, 3000 and 3600 series edgebanding presses are the successor models to the well-known HESS MOBIL PRESS which had been sold in the US for decades. After the close of the HESS PRESS Company in Germany in 2004, these completely new machines are now manufactured by the R. Beck Machine Company to our specifications. Hoffmann is proud to be the exclusive distribution partner for woodworkers in the US, Canada and Mexico. We stock an extensive inventory of wear and repair parts for MOBIL presses and many of the spare parts, for examples pressure plates, heating elements and pneumatic valves, will fit the older HESS MOBIL PRESS models, often with little or no modification.

(Old HESS MOBIL PRESS)

Good News for owners of older HESS MOBIL PRESS machines

Many of the spare parts (pressure plates, heating elements, pneumatic valves, thermostats, etc.) available for the current HOFFMANN MOBIL PRESS models will fit some of the older HESS MOBIL PRESS models. Please note that pneumatic or electrical parts are non-returnable and sometimes a little fitting may be required to make the parts works on old machines. Again, our presses are manufactured by a completely different company than the old HESS PRESS line and we do not have drawings or any technical details on the old machines.

Who needs a MOBIL PRESS?

The HOFFMANN MOBIL 2500, 3000 and 3600 series edge banding presses are the perfect choice for woodworking companies that manufacture hospitality, commercial and residential table tops, shelves, cabinets, architectural millwork, library and bank interiors, commercial and store displays, restaurant booth and tables, to name a few applications.

Aside from standard square or butt-joined edges mitered corner edges can be applied quickly and easily. An adjustable miter stop is used to precisely align the inside corner of the mitered edge band with the edge of the panel, resulting in tight fitting miter joints on every panel.

Hoffmann MOBIL PRESS benefits in a nutshell

1. Compared to manual gluing operations using bar clamps, etc. the MOBIL

edgebanding press, by using heat and pressure, can attach a solid

wood edge, 1” thick, in minutes. The same glue-up at room

temperature would take at least 45 minutes.

2. Compared to a standard edgebander, the MOBIL PRESS can quickly apply edge

profiles from as thin as veneer thickness up to 2” thick and 4” wide.

3. Compared to a large edgebander, the MOBIL PRESS can accurately apply mitered

edges up to 2” wide, creating perfect miter joints.

4. Compared to an expensive and complicated high-frequency glue clamping system, the MOBIL PRESS does not use HF-energy and does not require special adhesives, catalysts or other chemicals. It is a simple and safe operation, accomplished with regular PVA white or yellow glue that is already being used in virtually every woodworking shop.

For the above reasons, HOFFMANN MOBIL presses have proven to be an ideal complement to existing edgebanders in many production facilities.

Look at some interesting MOBIL PRESS details:

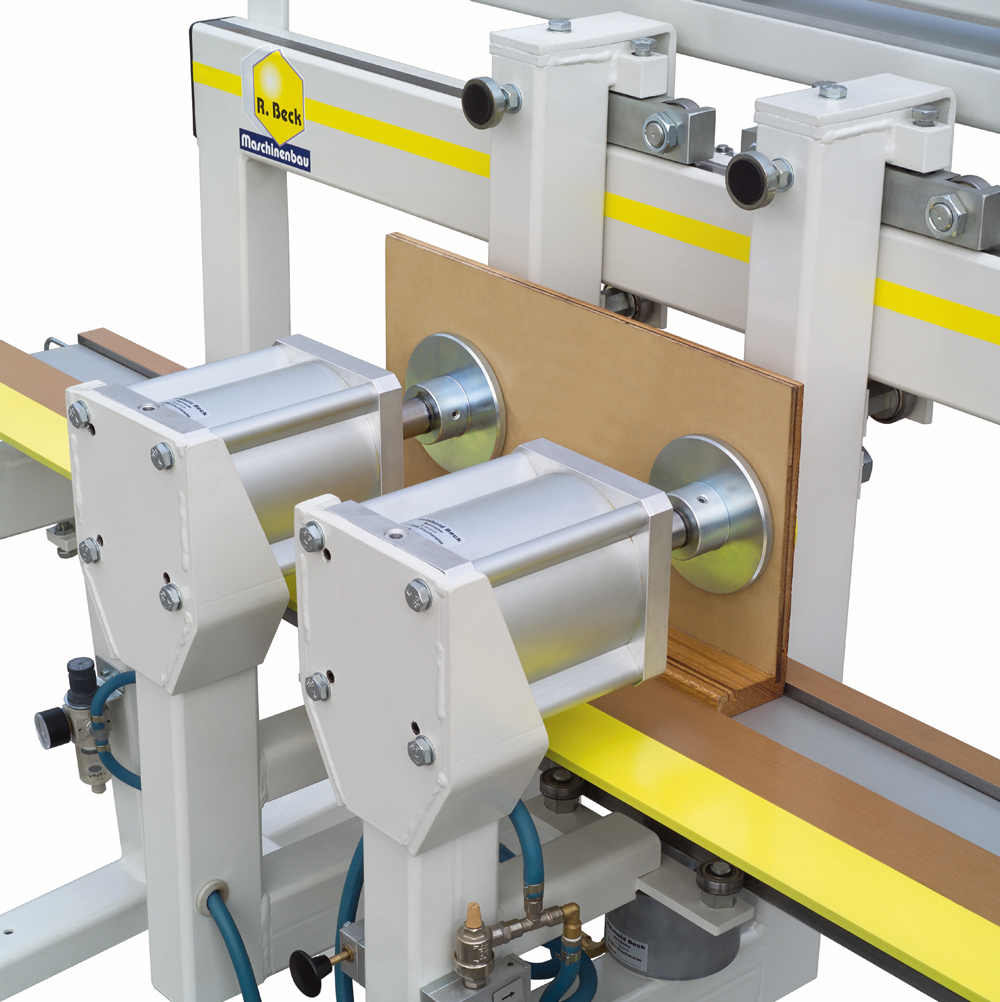

The machines are equipped with two heating elements and two (MOBIL 2500), three (MOBIL 3000) or four (MOBIL 3600) pneumatic clamping stations. Each station features two horizontal clamping cylinders to secure the panels and two vertical short-stroke cylinders to pull the panels down onto the edgebanding.

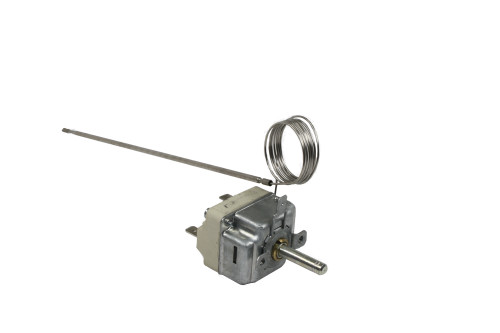

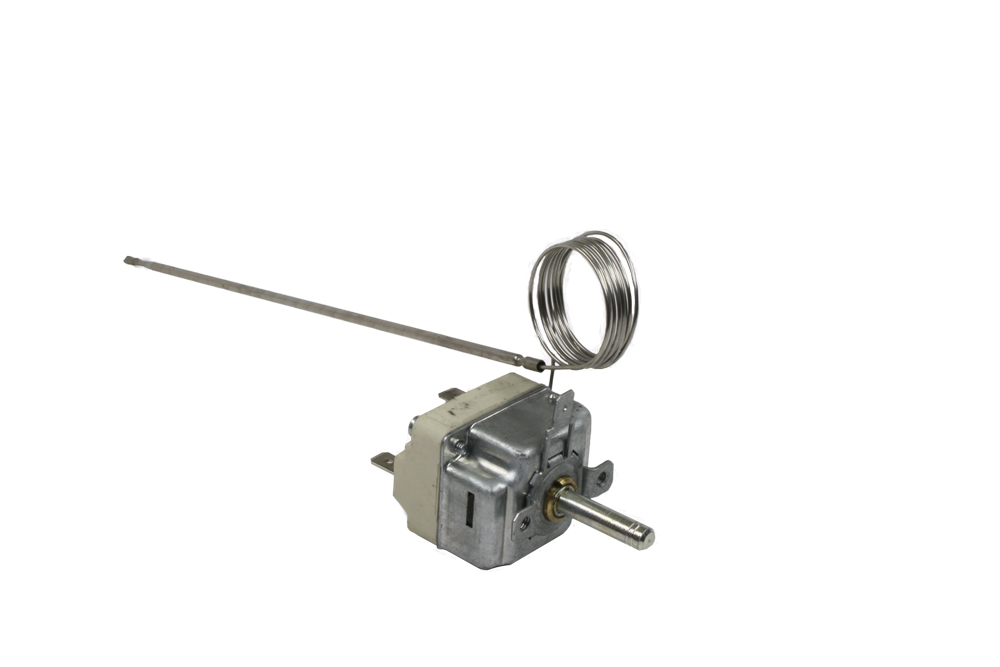

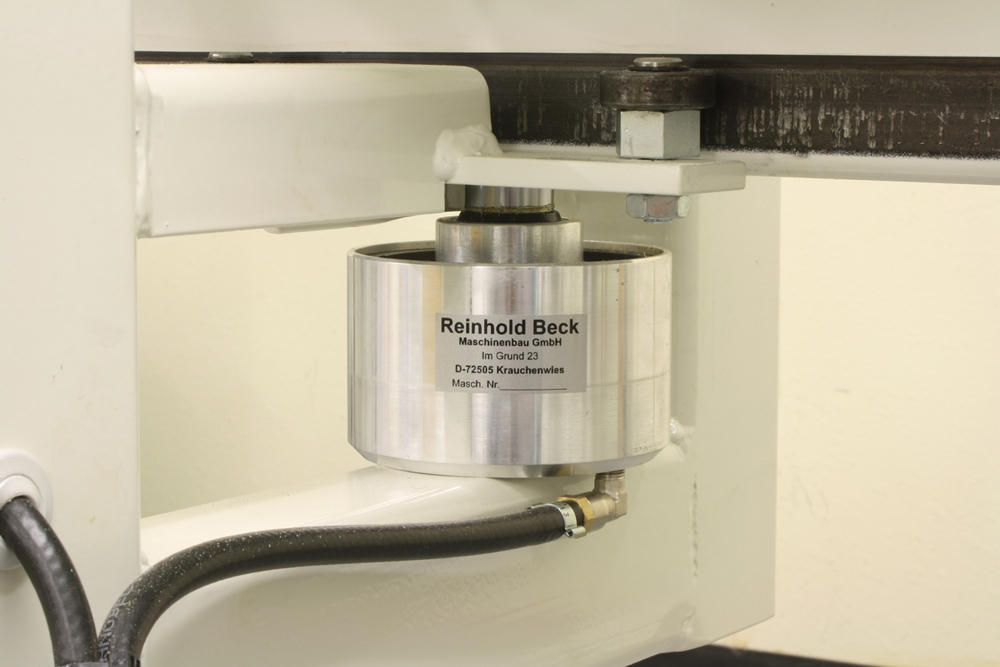

Close-up of Hoffmann MOBIL PRESS heating element with thermostat

Typical Hoffmann MOBIL PRESS clamping station

Standard white or yellow PVA glue is used in combination with the adjustable heating elements to attach up to 2” thick and up to 4” tall solid wood edges without the need for special glue, splines or additional fasteners. Glue bond strong enough to remove the panel from the press is achieved in approx. 2-3 minutes on 1” thick wood edges – less time is needed for thinner stock. An adjustable steel edge guide assures consistent and parallel edge alignment and edges up to 4” wide (waterfall edges) can be processed.

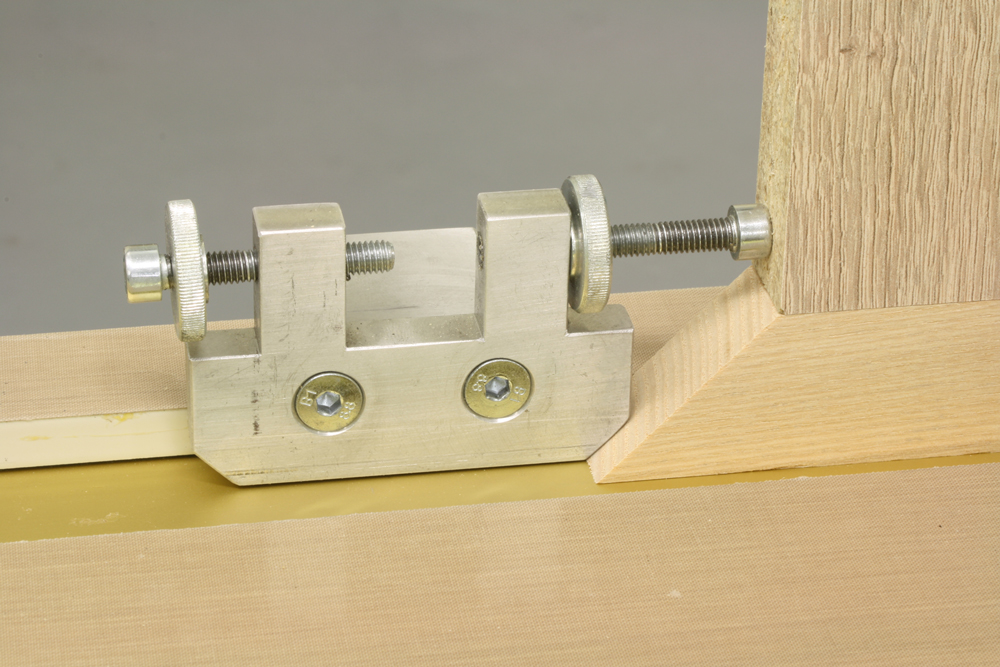

MOBIL PRESS miter stop with adjustable contact bolt and lock-nut

In addition to standard square or butt-joined edges mitered corner edges can be applied quickly and easily. The adjustable miter stop is used to precisely locate the inside corner of the mitered edge band with the corner of the panel, resulting in tight fitting joints on every panel. Two, three and four station MOBIL models allow continuous operation when processing small to mid-sized panels. By the time the last panel is placed and clamped in the machine, the first panel can already be removed. This is especially true for the three and four station Mobil 3000 and MOBIL 3600, which are ideal for this type of operation.

Vertical pneumatic cylinders used to pull panel down onto edgeband strip

How to operate the Hoffmann MOBIL Edgeband Press:

1. The operator begins by placing a wood strip in the pre-heating element to increase its temperature to the pre-set level.

2. Once heated, the strip is placed with the cool face down onto the heated platen of the pressing area.

3. After applying glue to the edge of the panel, it is set onto the pre-heated face of the edge strip (unlike with hot-melt edgebanders, panels are commonly processed vertically in the press).

4. The operator then activates the pneumatic push-button valves to clamp the panel against the back supports, then a second set of valves is activated and the lower cylinders pull the panel tightly onto the edgebanding strip.

5. During the pressing process the outside (cool) side of the edgeband strip is being heated from beneath. This equalizes the temperature in the pre-heated wood strip and reduces heat-induced stress for a better glue joint. The combination of heat and pressure quickly creates a very strong bond.

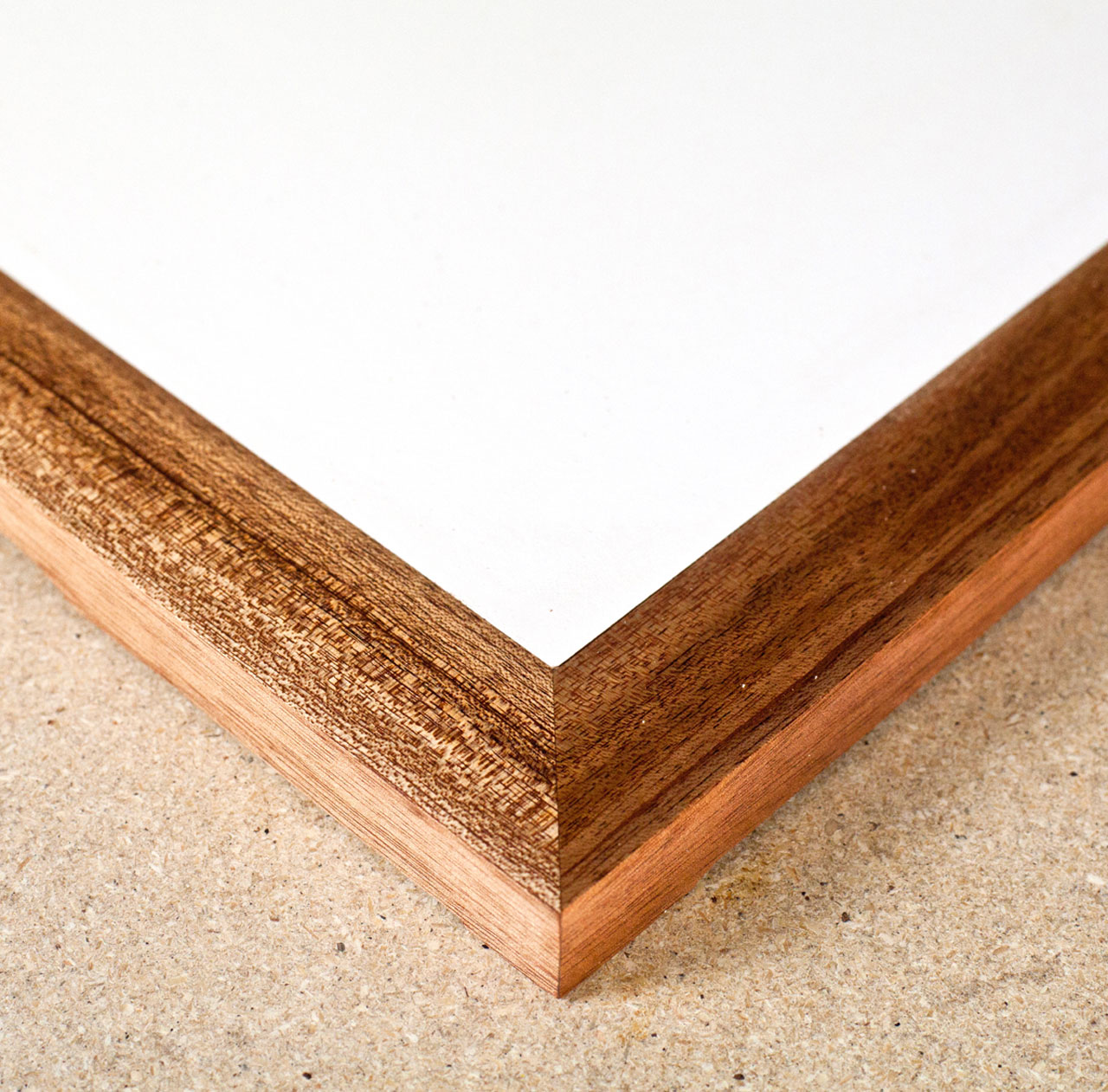

Product Samples:

Hoffmann MOBIL PRESS Standard Equipment

- Tilting panel support frame for easier handling of large panels (horizontal operation)

- Adjustable miter stop for precise corners on architectural grade panels

- Separate controls for each clamping station to allow for continuous operation

- Air regulator, filter, lubricator assembly installed

- One main heating bar and one pre-heating bar with individual thermostats

- Removable pre-heat bar for easier access during horizontal operation

- Anodized heating platens to reduce scratching and glue build-up.

- Heavy, solid welded steel frame and clamping stations on ball bearings assure long-term accuracy.

Product Videos

Videos Hide Videos Show Videos

-

Hoffmann MOBIL 2500, MOBIL 3000 and Mobil 3600 edgebanding press machine overview

This video gives an overview of the MOBIL 2500 and MOBIL 3000 ...

-

Attaching a solid wood edge strip with Hoffmann MOBIL edge press

This unedited, real-time video shows the actual process of att...

-

Attaching mitered wood edge with Hoffmann MOBIL edgebanding press

This video shows the actual process of attaching a mitered, so...