Product Description

Description:

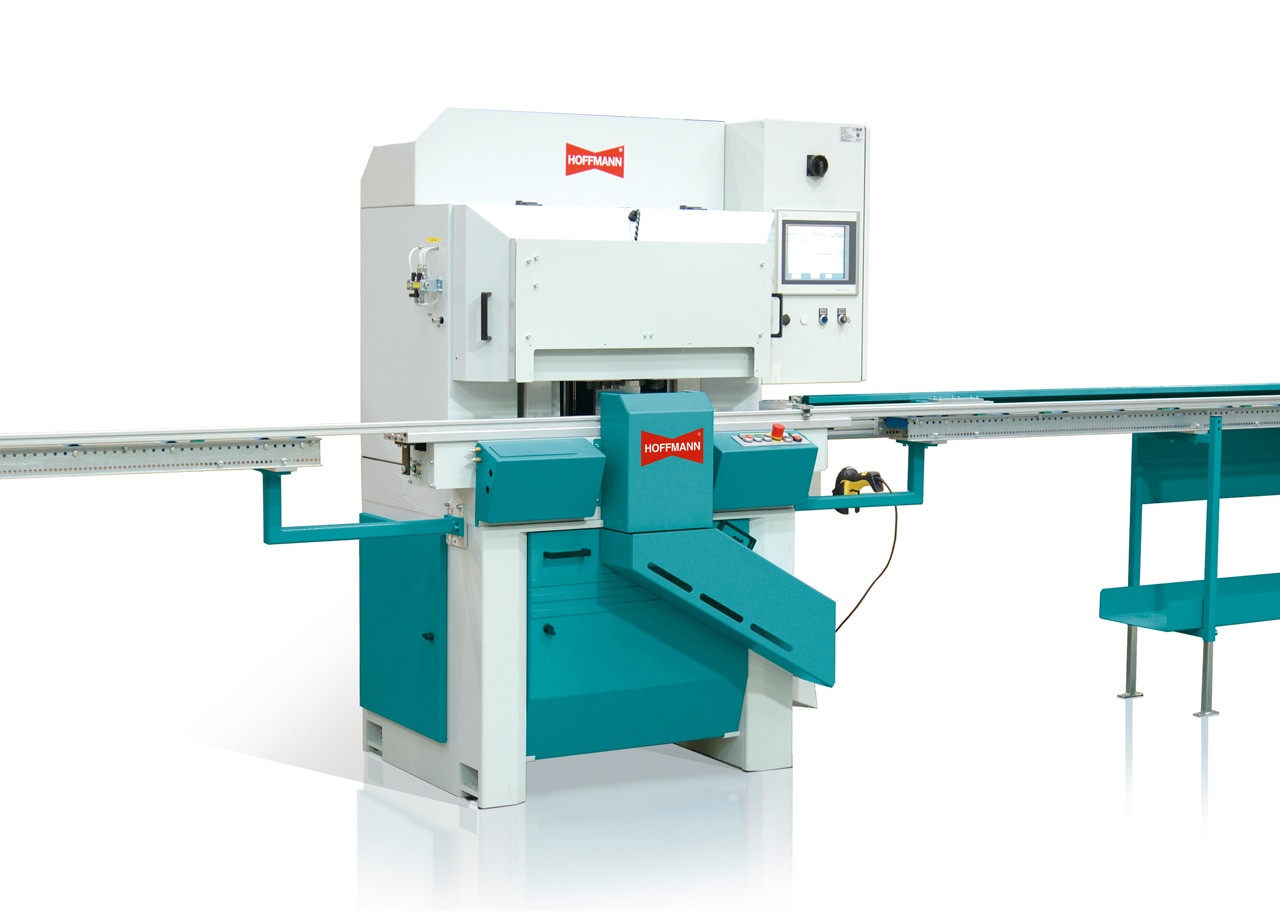

The Hoffmann MS40SF-NC double miter saw is equipped with two sawing and routing stations, mounted at a fixed 90 degree angle to each other. This assures perfect 45 degree miter cuts on two parts simultaneously.

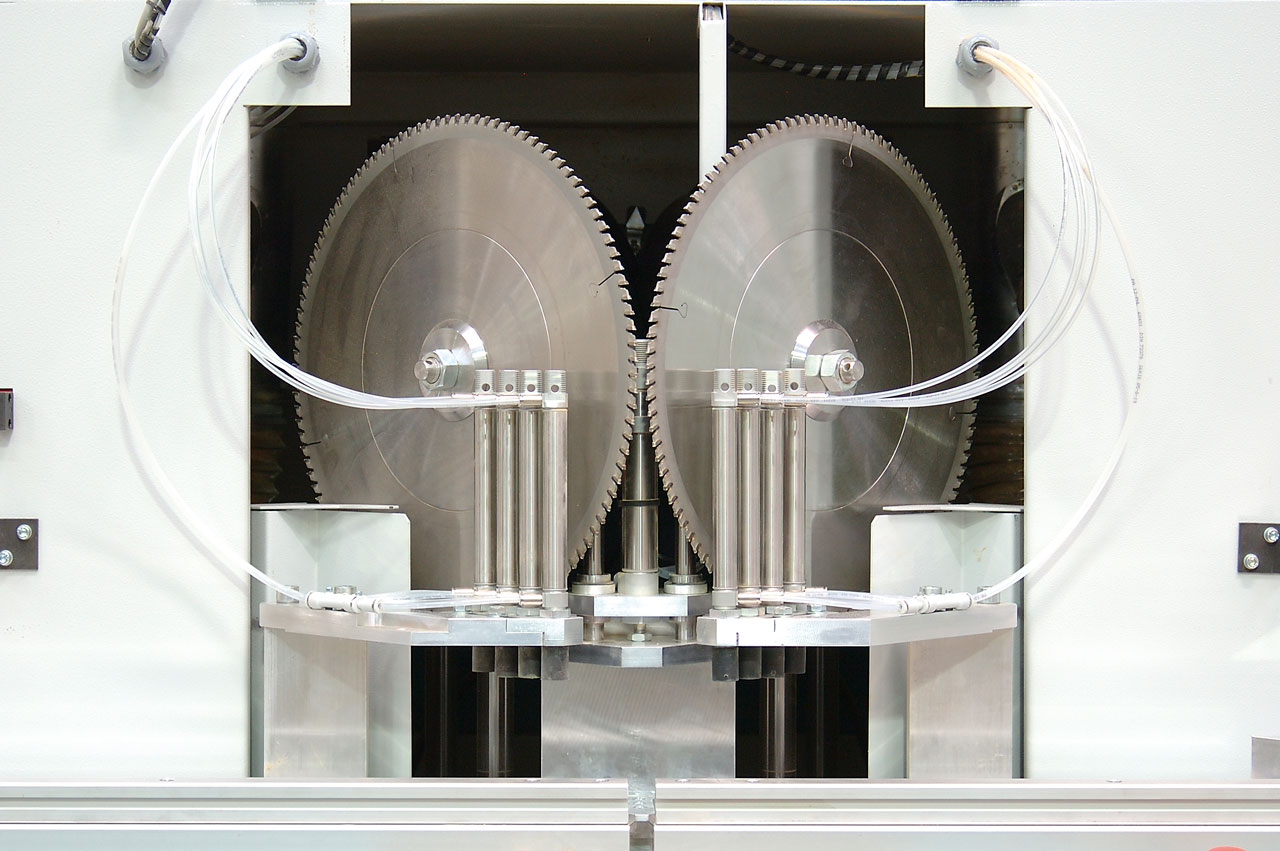

Each station consists of a saw blade to cut the material, and a routing head below to rout one, two or three dovetail keyways per miter.

MS40SF-NC saw blade detail

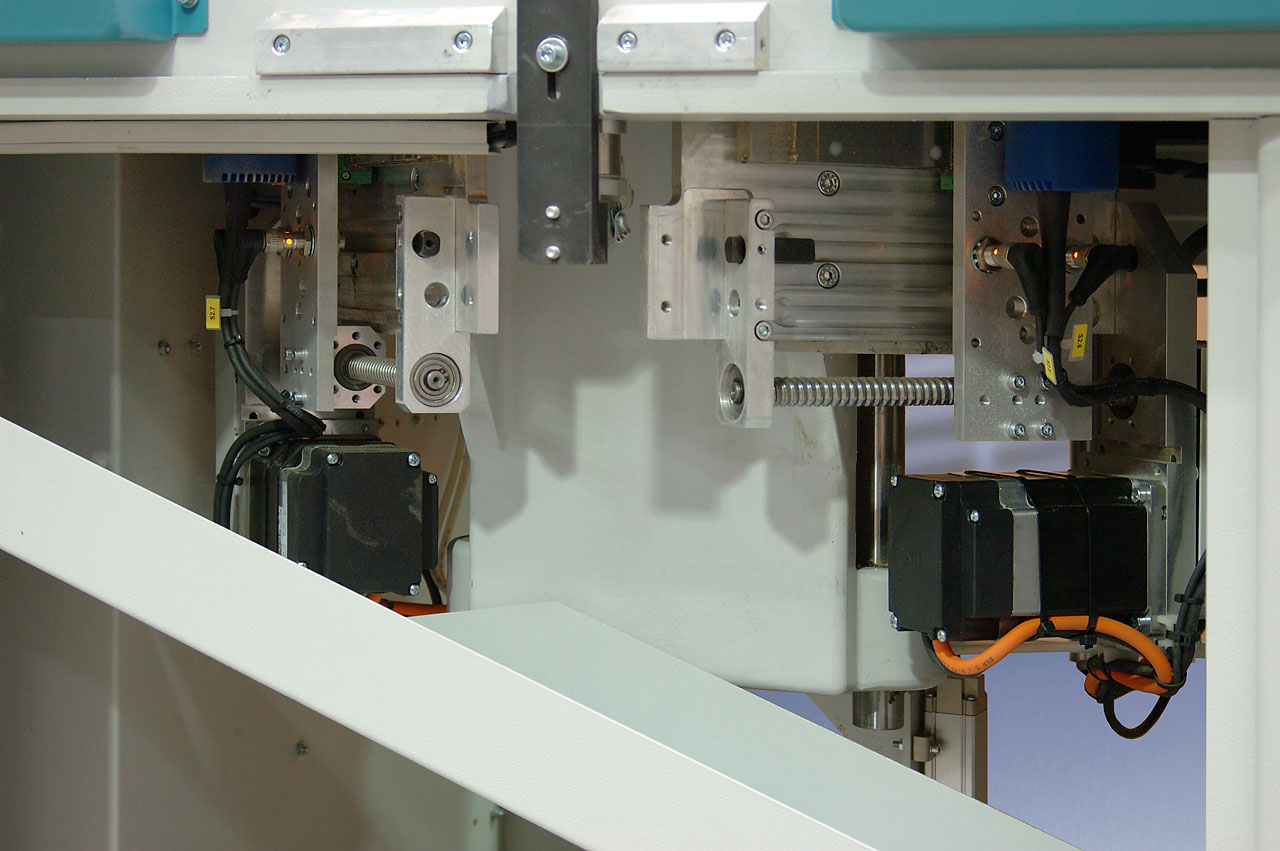

The machine features automatic adjustment of cutting length and automatic adjustment of keyway locations and keyway routing heights. Dual stepper motors are used to adjust keyway locations and keyway routing heights are controlled via electro-pneumatic sensors.

MS40SF-NC stepper motors used to adjust keyway locations

A large touch screen and industrial PLC unit are installed to control the various axes.

Displayed on the screen are, besides the actual cutting length, also the keyway locations and routing heights.

In addition, the system can be configured to display an image of the moulding being processed to aid in the operator’s visual verification. (.JPEG Images to be supplied by client).

MS40SF-NC touch screen

The hand-held scanner option allows the operator to scan a bar or QR code on the worksheet to quickly and accurately adjust the cutting length, routing locations and routing heights of the machine.

The QR code also includes the total quantity of frames to be made and the profile number which the software uses to display an image of the moulding for visual verification.

MS40SF-NC QR or bar code scanning

The ELA-2 positioning system was designed and is manufactured by Hoffmann in Germany.

The System is integrated into the operation of the MS40SF-NC in that the stop automatically moves out of the way to allow the machine’s tables to open for the routing process. Once the routing sequence is completed and the tables are in their home (closed) position again, the stop tracks back to the proper position.

The saw’s safety circuit is connected to the stop and vice-versa assuring utmost operator safety.

The positioning system is installed on the right hand side to function as a precise length stop system.

MS40SF-NC length stop detail

Applications:

Solid wood, MDF as well as plastics and composite profiles can be cut and routed for Hoffmann Dovetail Keys with speed and accuracy.

Non-ferrous metal, e.g. aluminum profiles, can be cut with appropriate saw blades (with dovetail routing sequence disabled by operator).

Typical applications include window and door components made of wood, PVC or aluminum, mitered cabinet doors, applied moulding frames for wall paneling and doors, decorative trim and casing profiles, architectural millwork, shutter frames, store fixtures, shelves, wood components for the furniture industry, plastics and aluminum parts for the RV industry, picture and mirror frames, etc.

Machining sequence:

- Operator enters information for cutting length and keyway locations on touchscreen manually or via QR code scanner (or recalls previously stored parameters), then places work-piece on machine table.

- Operator activates two-hand safety controls – pneumatic clamps secure material on table.

- Saw blades cut through material and retract up to their home position.

Triangular waste piece is secured during cutting operation and ejected toward front of machine into scrap chute. - Router motors move up and rout keyways to pre-set lengths, then retract below tables.

- Pneumatic clamps release the material and operator removes finished part.

Options:

Hoffmann MS40SF-NC double miter saws are built to order we work closely with our clients to determine which modifications or options are required to meet customer’s production needs.

Available options include:

- High-frequency router motors for extended service life.

- Longer cutting lengths for automatic Positioning System

- In-feed Pusher System instead of out-feed Stop System

- Other models available for sawing operations only (Hoffmann MS 35 and Hoffmann MS 40) and models with manual cutting length and keyway position adjustments (Hoffmann MS35SF and Hoffmann MS40SF)

Technical Specifications:

- Power 230 Volts, 3 P, 25 Amp

- Air Supply 90 psi – 3 cfm

- Saw heads 2 x 2 1/2 HP, 3,470 rpm

- Saw blades 400mm diameter, carbide tipped

- Router heads 2 x 500 watt router motors

- Installed router bits Hoffmann W-2 solid carbide

- Available router bits Hoffmann W-1, W-2, W-3

- Cutting capacity 4” width x 3.5” thickness

- Cutting angle fixed at 45°

- Minimum length 5”

- Maximum length 96”, longer lengths optional

- Operation two-hand safety controls

- Controls electronic operation with PLC

- Dust collection 2 x ports, 120mm diameter

Standard Equipment:

Hoffmann MS 40 SF-NC, ready for operation, including infeed support table, right hand side automatically adjusted positioning system, large touch-screen operator interface, NC-axes for keyway locations and keyway lengths, W-2 solid carbide router bits installed, air filter-regulator-lubricator assembly installed, two-hand safety operation, separate flow control valves for saw blade and router head feed rate, emergency-stop-switch, manual and toolkit.