Product Description

Overview:

Production-duty, freestanding dovetail routing machine with adjustable steel table and large work surface at comfortable working height. Machine features a tilting motor carriage (+/- 45º) and is designed to rout a single dovetail keyway with each machining cycle. For Dovetail Keys sizes W-0, W-1, W-2, W-3 and W-4.

Hoffmann PU2-TL pneumatic dovetail routing machine

Highlights:

The Hoffmann PU2-TL dovetail routing machine is a free standing production unit for multi angle applications like handrails, custom millwork, yacht interiors, store fixtures, displays, etc. This model can be set to rout either vertically up and down for all standard miters (a locking stop indicates the 0 degree mark), or it can be tilted up to 45 degrees forward or back.

Hoffmann PU2-TL motor angle scale

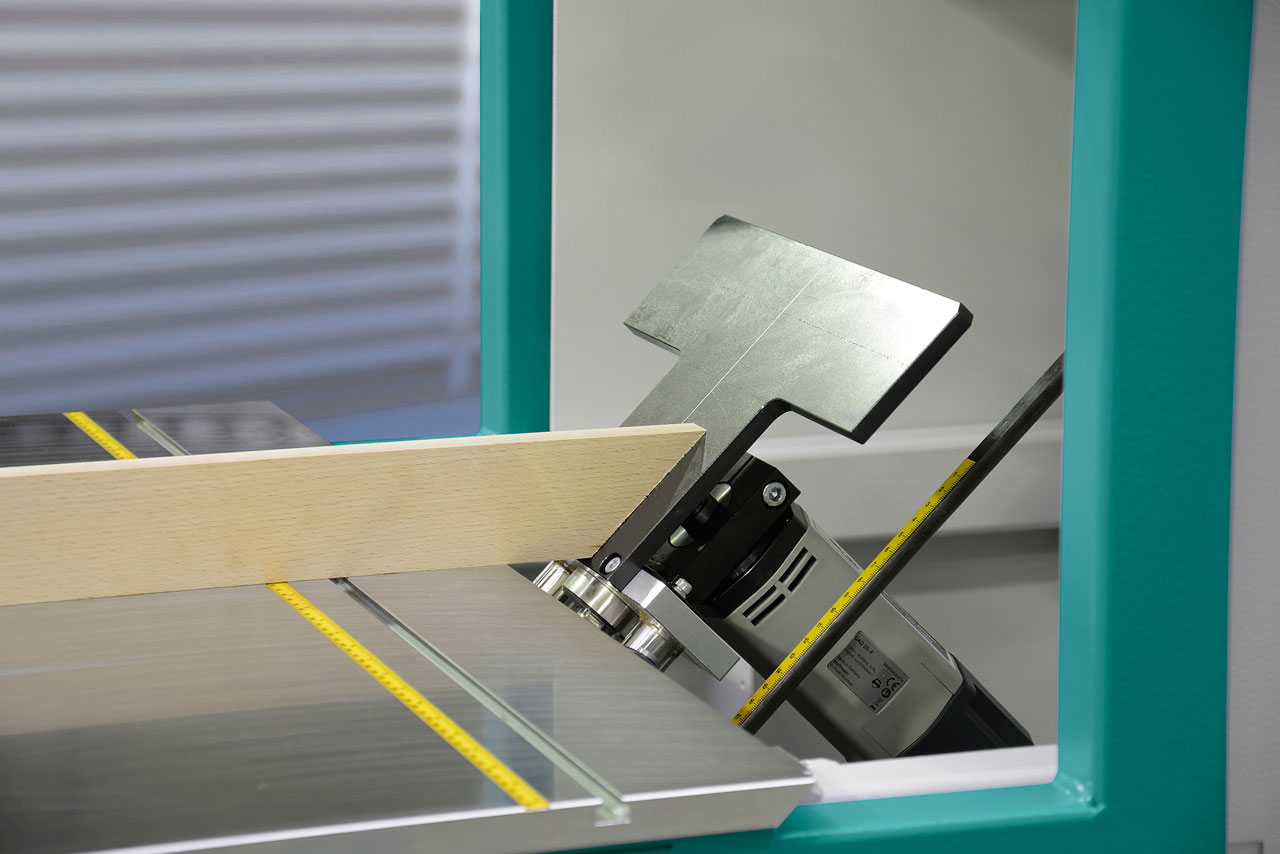

Set at an angle, the router will travel up and away from the operator if tilted back, and up and toward the operator if tilted forward. The adjustment is made with a hand wheel located at the front of the machine.

Hoffmann PU2-TL hand-wheels for angle and table location adjustments

The supplied 45 degree fence plate, which is guided in a keyway in the machine table, is used to accurately position the material on the table. The location of the dovetail slot for the Hoffmann Dovetail Key is adjusted by simply moving this fence plate or, in case of butt and angle joints, with the included square stops.

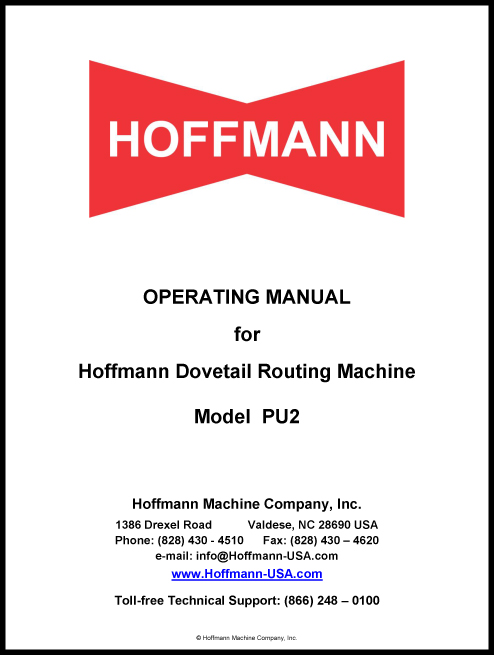

Hoffmann PU2-TL shown at +/- 45 degree motor tilt setting

Operation:

The keyway location is adjusted by positioning the guided center fence plate on the machine table; the keyway length (routing height) is adjusted by setting a height-stop rod to the desired setting.

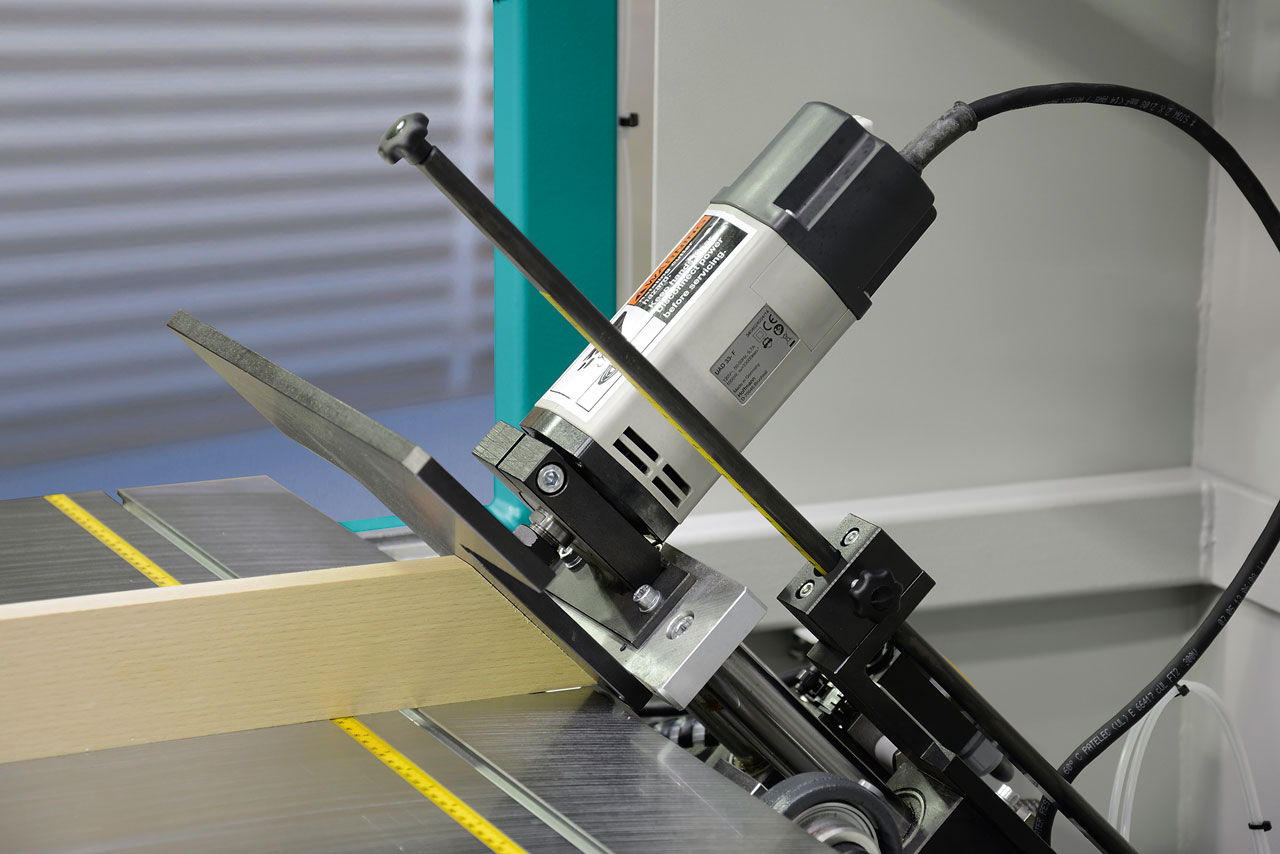

Hoffmann PU2-TL shown at 90 degree motor tilt setting for standard miter joint

Pressing the pneumatic foot pedal starts the machining cycle:

> Pneumatic clamp secures work-piece and motor is switched on

> Router head advances until pre-set height is reached

> Router head returns to home position and motor is switched off

> Pneumatic clamp releases work-piece

Output is approx. 16 routing strokes per minute, which translates into 2 completely processed rectangular frames. These numbers include material handling, but obviously depend on routing depth, feed speed, material flow and operator performance as well. Flow control valves on the main pneumatic cylinder allow the operator to adjust the upward and downward feed rate independently, depending on the material being processed. A 4" diameter dust collection port in the back is used to connect a central dust collection system.

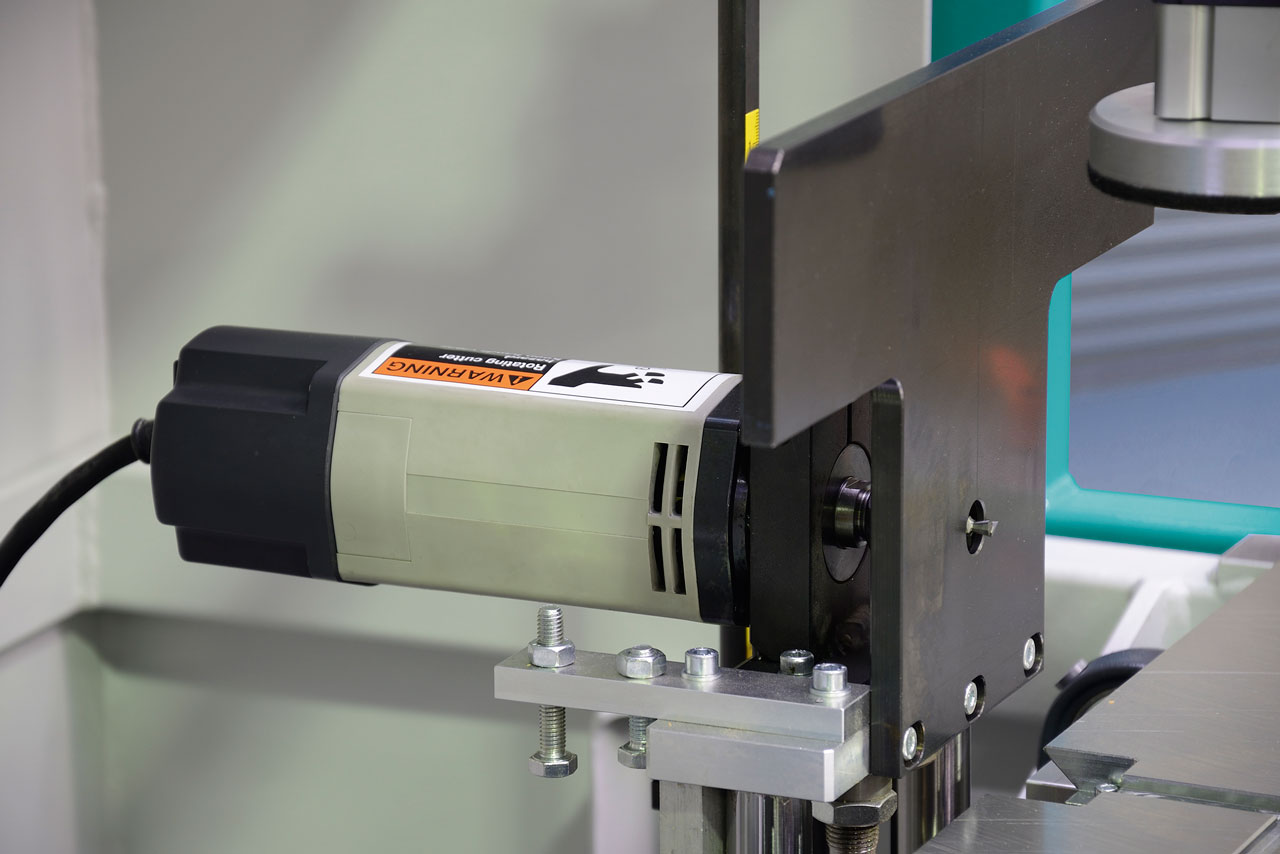

The supplied router bit is solid tungsten carbide, made to exacting specifications. Depending on the routing depth and the material to be routed, the useable cutter life is approx. 10,000 strokes, often times even more. Every machine is shipped with a tool kit and set-up jig, which allows a router bit change in only minutes.

Large 1,000 watt router motor and galvanized steel machine table

Standard Features:

Hoffmann Dovetail Routing Machine PU2-TL, freestanding floor model, ready for operation, with lockable Emergency-Stop, with air regulator-lubricator assembly, with W-2 solid carbide router bit installed, standard 45 degree center fence plate and square stop, toolkit and manual.

Technical data

Power Supply 120 volts – 8.3 Amps

Air Supply 90 psi - approx. 0.1 cubic foot/cycle

Motor 1,000 Watt motor with double front bearing

Motor speed 35,000 rpm at idle

Collet size 1/4”

Motor carriage guides 16mm diameter guide rods, precision ground

Operation pneumatic – dual cylinder design

Max. routing height 7 1/2”” – 190mm

Max. material height 12” – 304mm

Installed router bit W-2, solid carbide

Available router bits W-0, W-1, W-2, W-3 and W-4

Dimensions W/D/H 33 1/4” x 42 1/8” x 59 1/2”

Weight 418bs.

Warranty:

One year on parts and workmanship. Complete Hoffmann Warranty Terms apply

Click on images to download operating manual and related catalog