Product Description

Please click here to email us for a current freight quote – be sure to include your full address and whether you need optional services such as lift-gate service and/or residential delivery.

Overview:

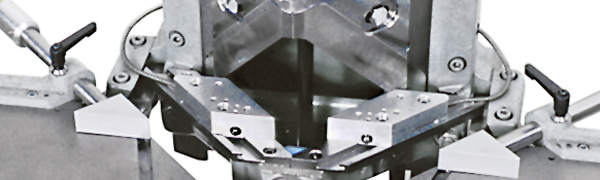

The MORSO NLEH is the electro-hydraulic version of the manual NFL model, with integrated oil pump, fluid reservoir and industrial PLC. All movements are controlled with touch-less proximity sensors and the two-hand safety controls on the front assure safe operation with both hands being far away from the cutting head.

Due to the fixed fence design, the machine is limited to 2 3/4” wide material but if that limitation is not an issue, it is a great choice for medium to higher production levels.

The machine features a heavy-duty steel frame with cast iron tabletop. The vertical travel of the cutting head, which is also made of cast-iron, can be adjusted depending on work-piece thickness in two positions with a selector switch, assuring comfortable operation.

Factory-fitted cast-iron extensions tables for left and right side are included and so is a full set of MORSO U-channel fences and flip-stop (optional DGS 1000 fence system is a popular upgrade).

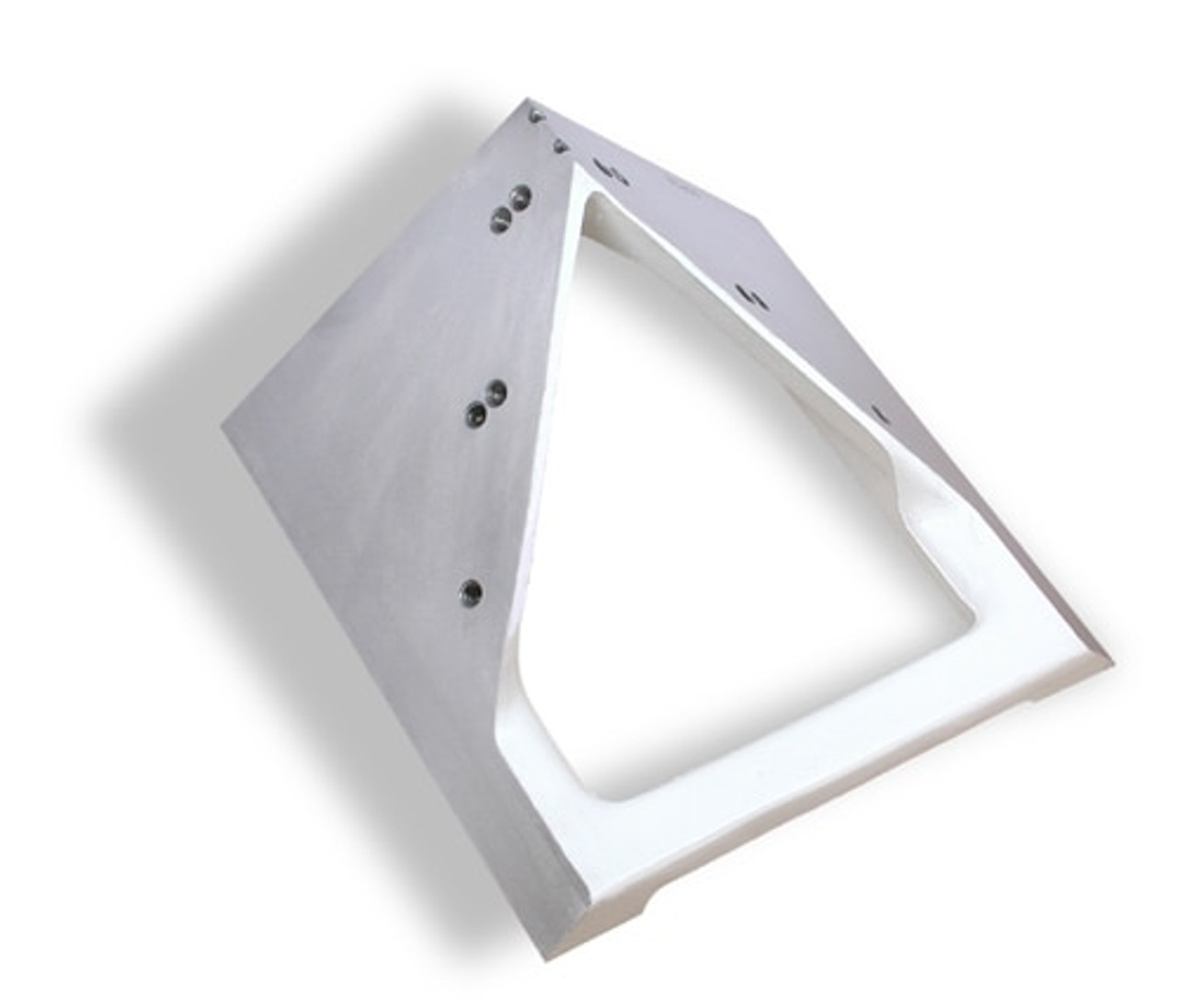

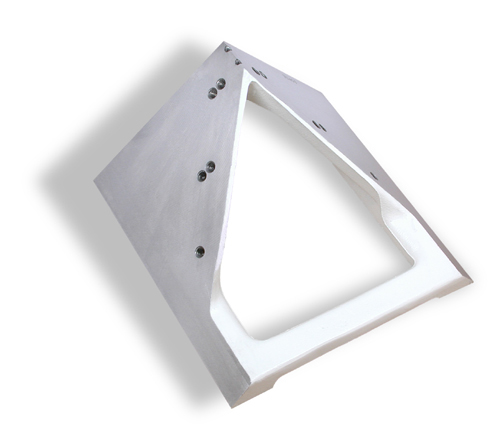

Optional smaller Cutting Head

To increase the range of applications, we offer smaller cutting heads for MORSO NLEH notching machines. These smaller heads are required to install 1/4”, 5/16” or 3/8” wide nose knives which are generally used for mullion or muntin joinery. The cutting heads can be replaced in only minutes and MORSO NLEH side knives fit on both heads; only the nose knives differ in design.

Two hydraulic clamps secure the moulding and the cutting head moves in until two proximity sensors in the cock-bead stops are triggered when the reach the bead edge. The hydraulic clamps are adjustable for different moulding widths and feature non-marring nylon pressure shoes.

Operation:

Beaded Face-Frame Notching Operation – full notch in stiles to accept cross rails (MORSO NLF shown)

Upon adjusting the cock-bead stops to set the notching depth, the moulding is placed on the machine table and one end is rested against a flip-stop.

Instead of moving the cutting head in and out with a hand-lever, and up and down with a foot-pedal, the operator simply presses two buttons on the to start the cutting cycle.

Electro-hydraulic cutting sequence:

- Hydraulic clamps secure the moulding against the fence rails

- The cutting head advances toward the operator

- Upon touching the moulding edge, sensors trigger two consecutive downward strokes of the cutting head (trim cut and finish cut)

- The cutting head returns to its home position and the clamps release the material

When set to the lower head position setting, the complete cutting cycle (trim cut and finish cut) is completed in approx. 2 seconds and the resulting cuts are smooth and free of tear-out!

Beaded Face-Frame Notching Operation – half notch in stiles to accept top and bottom rails (MORSO NLF shown)

A half-notch for top and bottom rails is cut into the left and right stiles in the same manner as a full notch. A “long arm” flip-stop is used to position the stile properly (the long arm is designed to reach past the cock-bead stops). For wider cross rails the stile is moved sideways after each cut until the desired notch width is reached.

Beaded Face-Frame Coping Operation – clipped corners on rails (MORSO NLF shown)

Upon adjusting the setscrews in the nylon center fitting, the stop is moved toward the cutting head and locked in place. The rail is placed on the table and pushed against the stop. The 45-degree corner cut on the bead is made in one cycle, multiple cuts are not necessary. The moulding is then flipped end-for-end and the process is repeated.

Options:

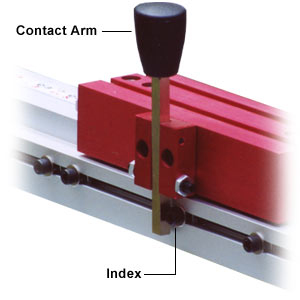

Optional DGS 1000 GlideStop Fence system for MORSO NLEH (MORSO NFXL shown)

A complete GlideStop fence system is available as an option for all MORSO notching machines.

This upgrade offers the following benefits:

Fully adjustable index stops can be set at any point along the fence rails for repeated accuracy

Index Stops can be spaced as close as 9/16" apart

Twenty index stops are included in the basic package, additional Stops can be added anytime

Index stops can be by-passed at any time without moving and re-setting

Self-adhesive tape scales on both fence rails for accurate positioning in 1/32" increments

Offers the benefits of twenty standard flip-stops at a fraction of the cost

Once set, the GlideStop uses a spring-loaded contact arm to register against the index bolts. This "mechanical memory" design has the accuracy needed to make precisely spaced face-frames, again and again. It is especially helpful for repetitive settings like drawer banks, door openings, etc. which do not change from job to job. In addition, the system allows the user to by-pass pre-set index bolts at any time, without having to move and re-adjust the stops!

The contact arm is simply tilted forward, sliding over the stop index.

The position of the GlideStop is shown on the tape scale, hairline pointers on each side make set-up fast and reliable. An optional digital upgrade is available if a digital read-out in inches and millimeters is preferred.

The patented GlideStop design uses a pressure bar to clamp against the fence rail. This avoids the marring of the rails by the locking lever, and it also assures positive clamping without "creeping". Simply slide the GlideStop to the desired position and turn the locking lever - done.

Automated Positioning Systems:

To drastically increase productivity and accuracy when manufacturing beaded face-frames we offer automated positioning systems with and without integrated cut-off saws.

Link to systems without cut-off saws

Link to systems with cut-off saws

These systems are available with manual MORSO NFL and NFXL or electro-hydraulic MORSO NLEH and NXLEH notching machines.

Retrofitting these systems to existing MORSO machines is also an option.

Please note that positioning systems cannot be used with manual MORSO NM notching machines.

MORSO NLEH Standard Features:

MORSO NLEH electro-hydraulic notching machines for beaded face-frames include:

- 220 volts, 60 Hz, 10 Amp., single or three-phase electrical power connection

- Two-Hand safety control push-buttons on front

- safety guard

- scrap chute

- four short-arm flip-stops and two long-arm flip-stops

- left and right hand side cast iron table extensions

- left and right hand side aluminum fence rails

- one set of original MORSO side knives, factory ground and honed

- one 3/4" wide nose knife and one 1" wide nose knife, factory ground and honed

- detailed instructions incl. parts diagrams

Warranty:

Mechanical parts are warranted for twelve months.

Complete MORSO warranty terms apply.

Freight Cost Information:

All MORSO NLEH manual notching machines are shipped in a plywood crate which is attached to a pallet. This requires the use of a common carrier trucking company but greatly reduces the risk of transport damage to the machine.

If you would like to get a freight quote or place an order for this machine, please contact our office toll-free at (866)248-0100.

MORSO NLEH notching machine - technical data:

|

Electrical Connection |

220 volts, 60Hz, 15 Amps, single or three phase |

|

Hydraulic System |

Self-contained fluid circuit, 1,200 psi max. pressure, 1.85 gal/min |

|

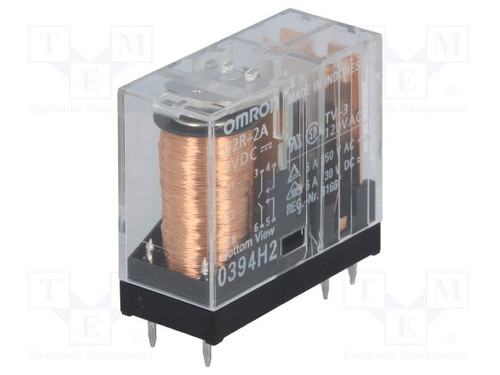

Controls |

OMRON industrial PLC and inductive proximity sensors |

|

Safety |

Two-Hand safety push-buttons on front and Plexiglas safety shield |

|

Max. Moulding Width |

2 3/4" (70mm) |

|

Max. Moulding Thickness |

6 1/4" (155mm) |

|

Machine Controls |

manually controlled with hand lever and foot pedal |

|

Nose Knife Capacity |

1/2" - 1" width (1/4", 5/16", 3/8" nose knives require smaller cutting head) |

|

Extension Tables |

heavy cast iron, machined surface, 30 3/4" long, one left and one right hand side |

|

Fence Rails |

silver anodized aluminum, 59 1/2" total length, one left and one right hand side |

|

Table Height |

33" - floor to table surface |

|

Width Including Fence Rails |

118" |

|

Weight |

320 lbs. |

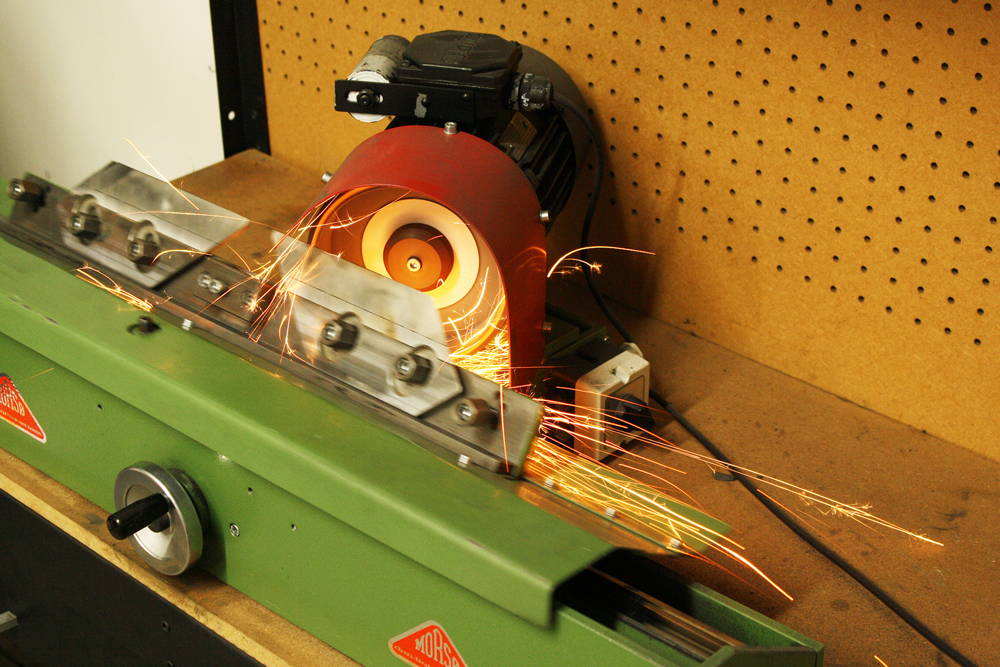

MORSO knife sharpening services

Whichever MORSO notching machine you choose, be sure to always return side knives and nose knives to Hoffmann, Inc. for sharpening. These knives require a special hollow grind geometry as well as hand-honing to achieve a razor sharp edge. Most commercial tool sharpening services do not have the correct equipment for these knives and once flat-ground, they are pretty much ruined.

We use a custom grinding machine made by MORSO to get your knives back to factory-new condition.