Product Description

Overview

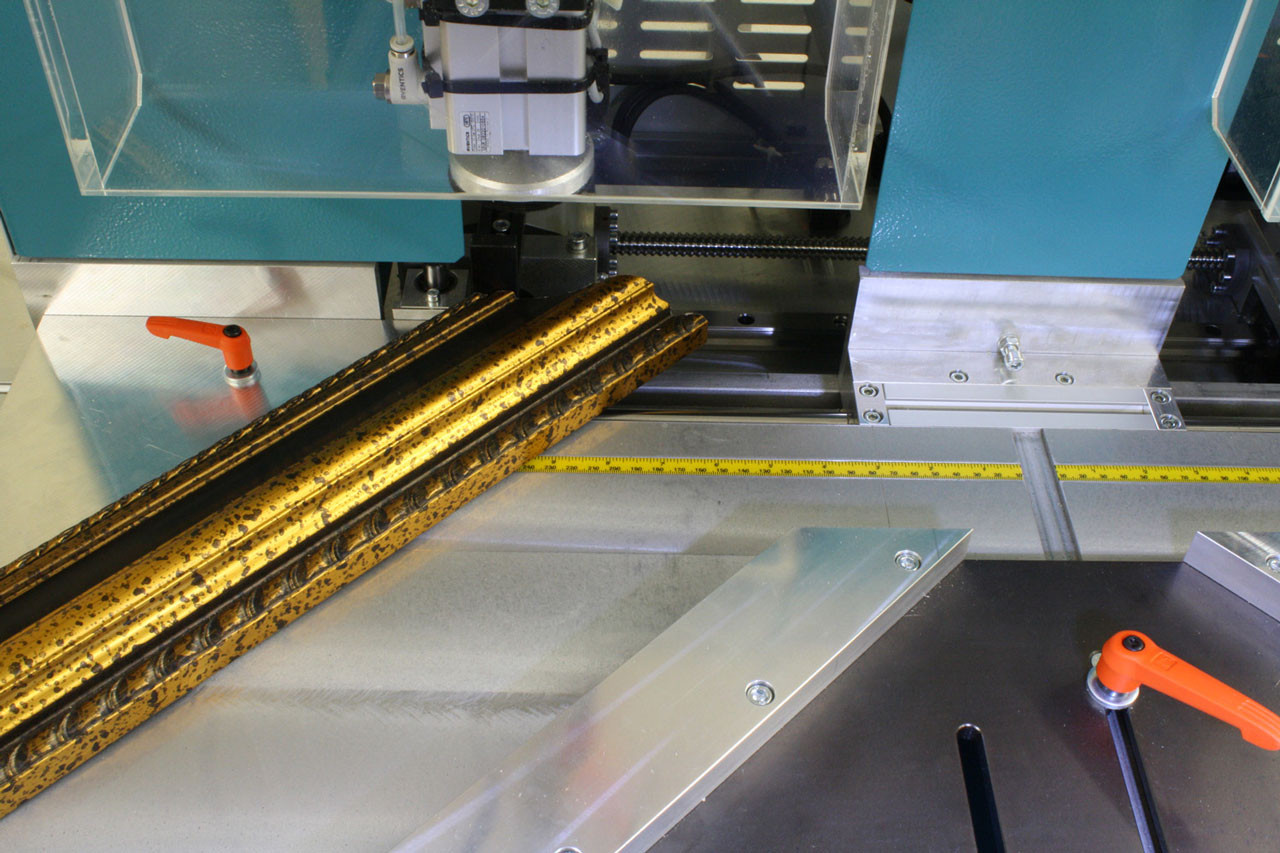

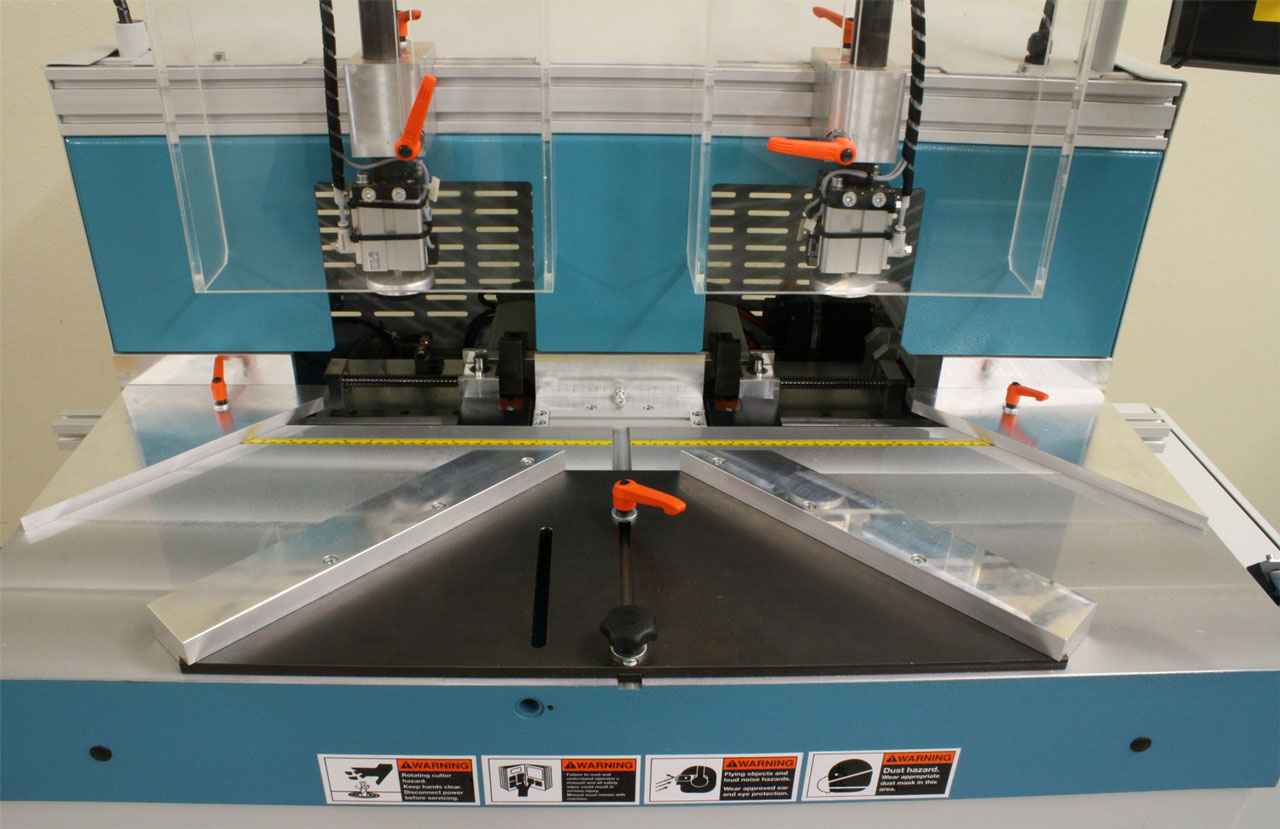

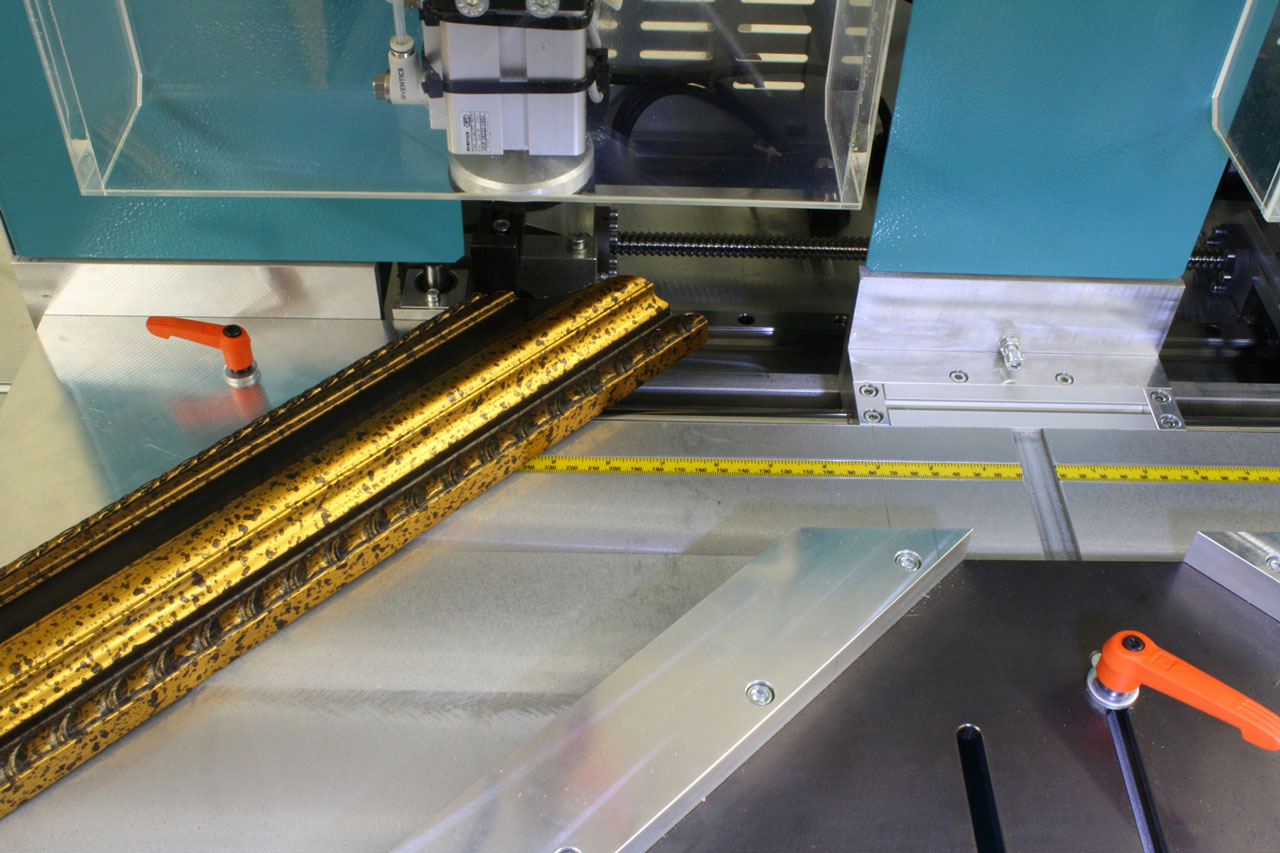

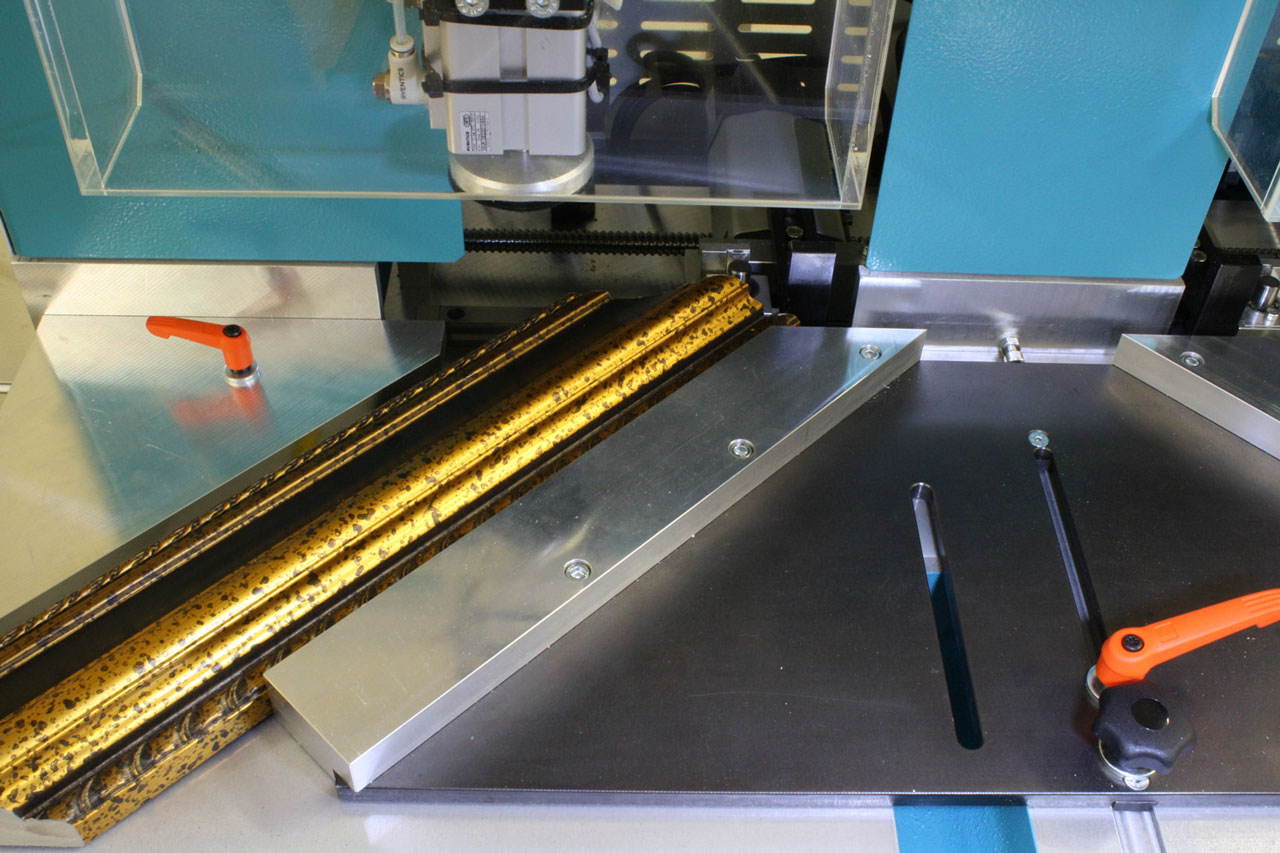

The Hoffmann PP2-NCF freestanding, automatic dovetail routing machine is equipped with two high speed router motors to process two workpieces simultaneously. The supplied 45 degree fence plate, which is guided in a keyway in the machine table, is used to accurately position the material on the table.

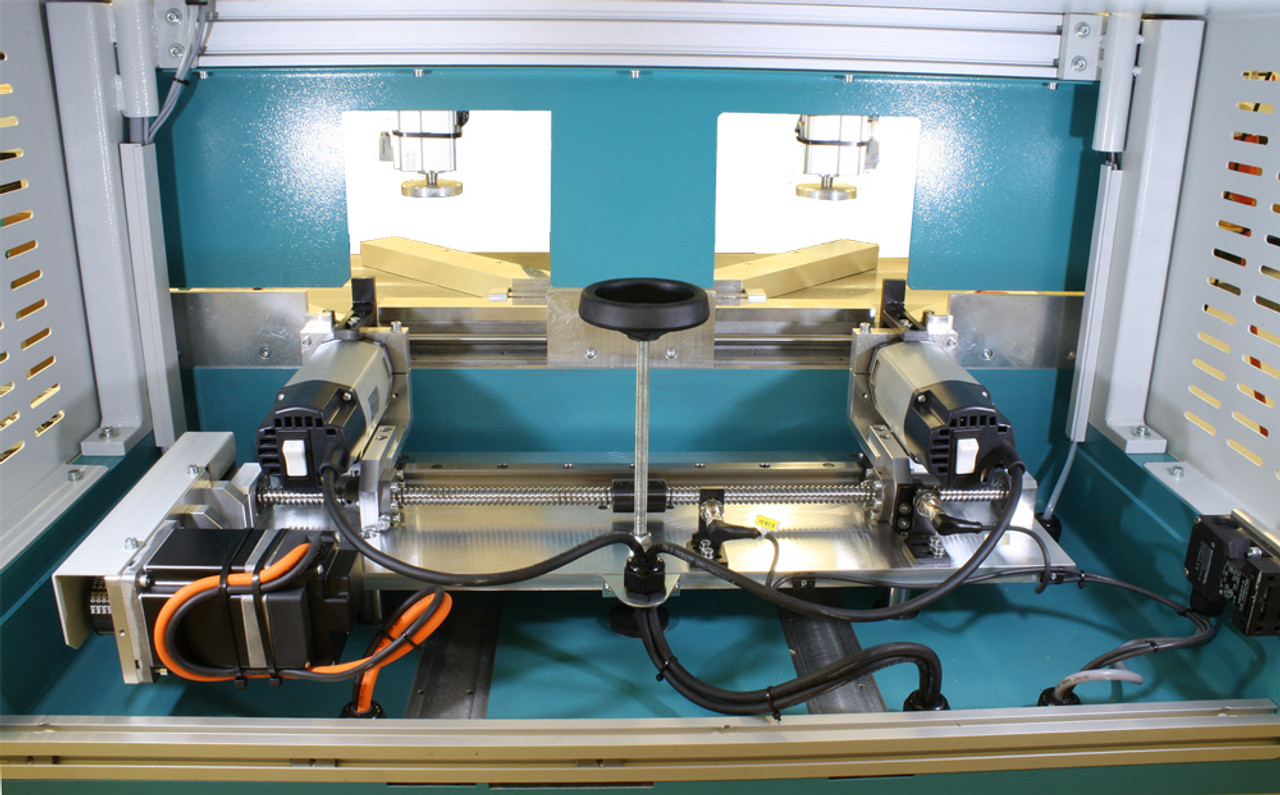

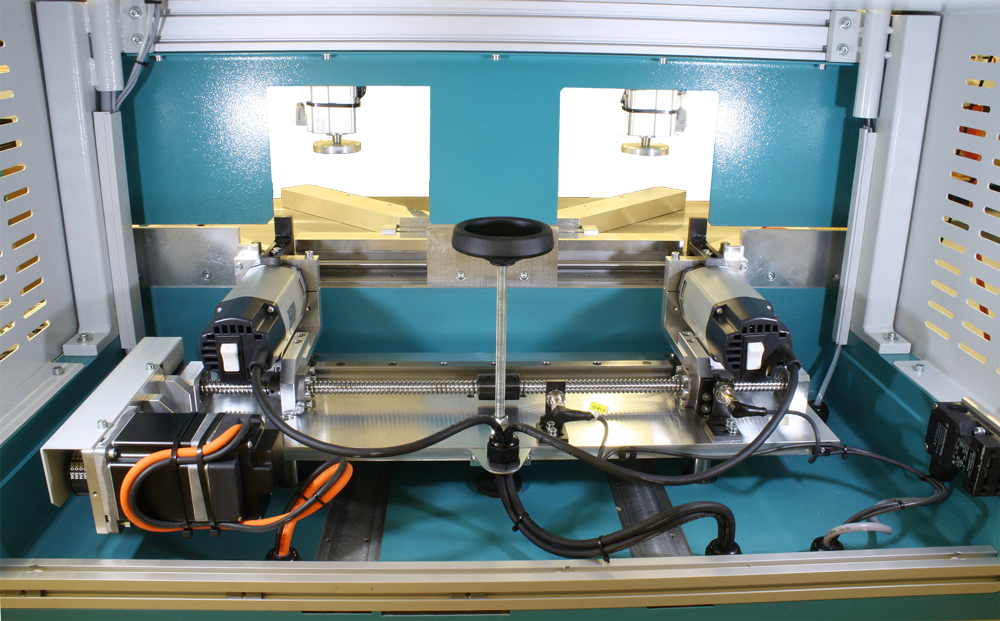

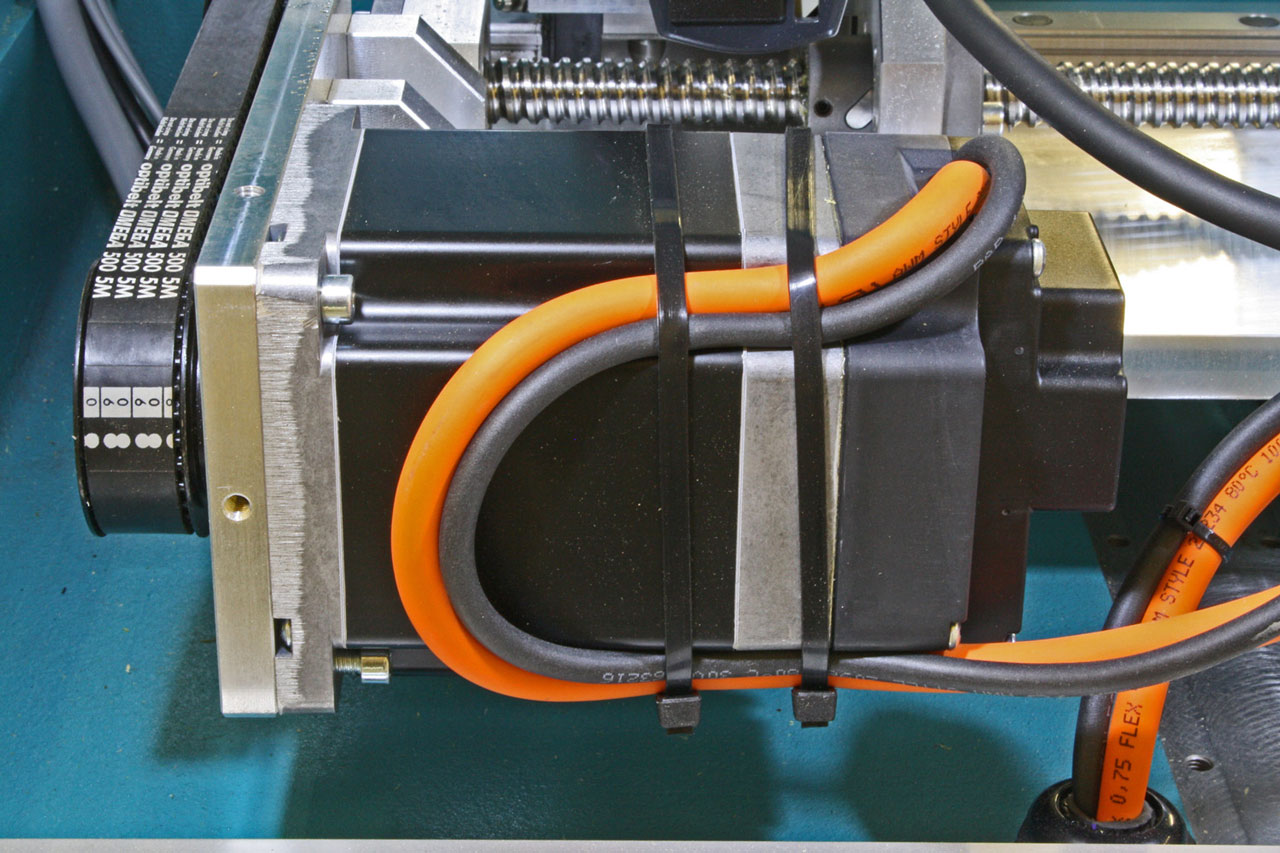

Quality Construction with hardened ball and screw drive and NC stepper motor

The motors brackets are mounted on a precision ball-and-screw spindle for fast and accurate lateral positioning via servo motor. The routing height (upward travel of router motors) is also electronically controlled to within 0.5mm.

Fully programmable for wide range of profile dimensions

The operator can select to rout only one, two or three dovetail keyways into each miter face and a different routing height can be programmed for each keyway location.

Keyway locations and routing heights can be entered manually on the color touchscreen.

Keyway locations and routing heights for a given moulding profile can be stored with the unique moulding number for later recall.

One machine - many applications

Hoffmann PP2-NCF is the ideal dovetail routing machine for operations that use a number of different moulding sizes frequently. Typical customers include picture frame and mirror frame operations, millwork and cabinet shops, moulding suppliers and plantation shutter manufacturers.

Increased productivity and quality from perfectly aligned dovetail keyways

Being able to program keyway locations and storing the data with a customer defined file name, e.g "Shutter Z-frame, large" or "Nantucket Mirror Frame" allows for quick and reliable recall and assures every pieces of moulding has Hoffmann Keyways routed in exactly the same locations. this assures perfectly aligned and tight miters every time.

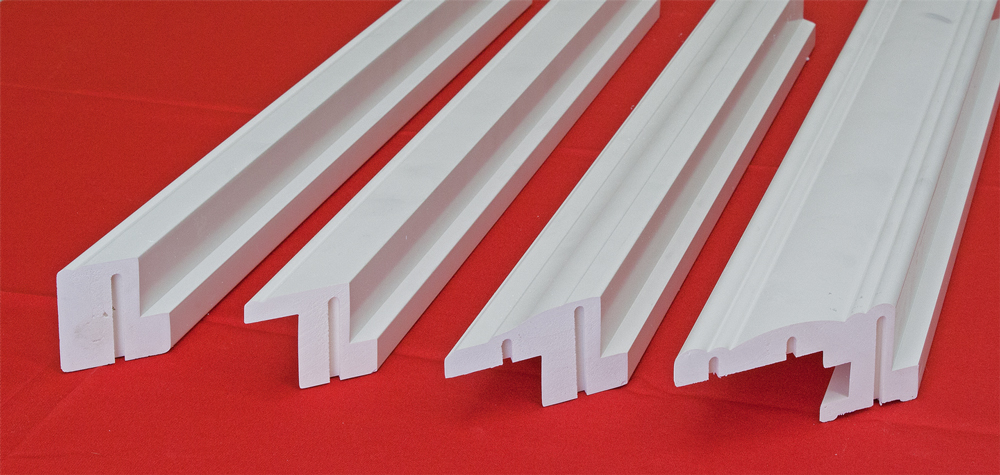

Plantation Shutter Manufacturing

For Plantation Shutter Operations we offer optional support blocks for various Z-Frame Moulding. These precision-machined aluminum support blocks are manufactured to customers' specifications to match their profiles perfectly We also offer additional horizontal hold-down clamps to secure difficult to machine profiles.

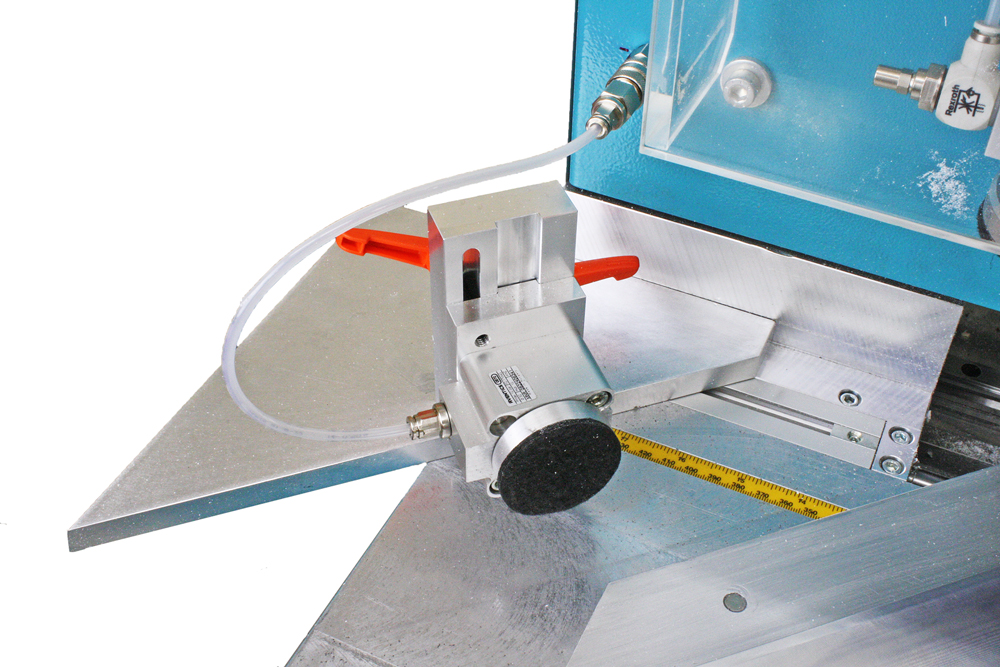

Optional horizontal material clamps for shutter profiles

When processing shutter frame material, especially larger Z-Frame stock, we recommend the addition of left and right hand side horizontal material clamps for best results. The clamps are connected to main pneumatic circuit and controlled with the foot switch.

Additionally, a selector field CLAMP INDIVIDUALLY on the touch screen allows the operator to only activate the vertical and horizontal clamp one side at a time - this is helpful when working with shutter stock longer than approx. 3 feet.

Double Routing Option for PVC profiles

PVC shutter profiles tend to vary in composition and density form manufacturer to manufacturer and some material requires each keyway to be routed twice for best results. The first pass cuts the dovetail keyway and the fast, second pass cleans out any remaining PVC chips to easier insertion of Dovetail Keys during assembly. Since not every material requires double routing, we have added a selector field on the touch screen.

Recent installation in a plantation shutter production facility

Machine Operator being trained by Hoffmann Technician

Machine Operator producing quality PVC plantation shutter frames shorty thereafter

Inside or Outside Reference Edge

Depending on type of material and finished product, the operator can select to use either the inside edge or the outside edge of the material as reference edge.When placed against the center fence plate, the outside edge is used as reference and the keyway locations are displayed on screen as measured from the miter tip to the center of the kewyay.

Material referenced against inside edge Material referenced against outside edge

Adjustable vertical material clamps

Hoffmann PP2-NCF features large work surface which is designed to be at a comfortable working height, the router motors are controlled by a contactor and a 4” dust collection port is located at the back for connection to a central dust collection system.

Operation:

The machine is equipped with a foot switch to activate the material clamps.

Upon depressing of the switch, the following routing sequence is initiated by pressing a START button on the control panel:

- motors are switched on and router heads advance up until the pre-set height position is reached, then return below table

- router heads move to second or third location and repeat routing sequence

- pneumatic clamps release workpieces

Output is approx. 16 routing strokes per minute, which translates into 4 completely processed rectangular frames. These numbers include material handling, but obviously depend on overall frame size, routing depth, feed speed, material flow and operator performance as well. Flow control valves on the main pneumatic cylinder allow the operator to adjust the upward and downward feed rate independently, depending on the material being processed. A 4" diameter dust collection port in the back is used to connect a central dust collection system.

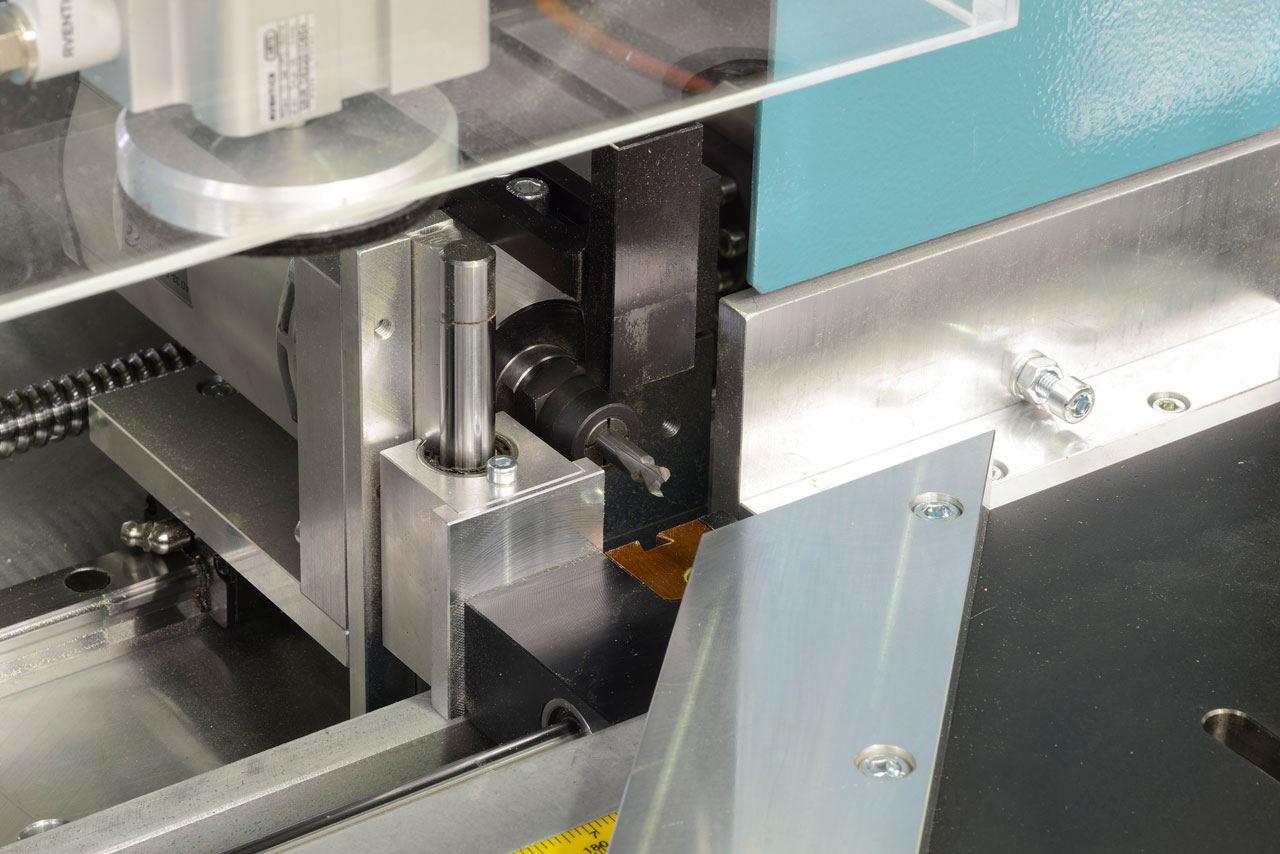

Industrial tungsten carbide router bits for long service life

The supplied router bit is solid tungsten carbide, made to exacting specifications. Depending on the routing depth and the material to be routed, the useable cutter life is approx. 10,000 strokes, often times even more. Every machine is shipped with a tool kit and set-up jig, which allows a router bit change in only minutes.

PP2-NCF Standard Features:

Hoffmann PP2-NCF Dovetail Routing Machine, with color touch screen on adjustable support arm, with HOFFMANN software package installed, ready for operation, with two W-2 carbide router bits, with standard 45 degree fence plate and square stop, with air filter-regulator unit installed, including toolkit and manual

Hoffmann PP2-NCF Technical Data .

| Power supply |

220 volts, 18 A., 3 ph |

| Motor size |

2 x 1,000 watt |

| Motor speed |

33,000 rpm |

| Compressed Air Supply | 90 psi |

| Router Collet Size | 1/4" |

| Max. material width | 5" |

| Max. material height | 5" |

| Max. routing height | 4" |

| Number of Keyway locations | up to 3 per miter |

| Number of different Keyway lengths | up to 3 per miter |

| Supplied router bits | W-2 solid carbide |

| Available router bits | W-1, W-2, W-3 |

| Dust collection port | 4" diameter |

| Approx. net weight | 528 lbs. |

Warranty:

One year on parts and workmanship. Complete Hoffmann Warranty Terms apply.

Click on images to download operating manual and related catalog

Product Videos

Videos Hide Videos Show Videos

-

Hoffmann PP2-NCF programmable dovetail routing machine for shutter frames

Hoffmann PP2-NCF programmable dovetail routing machine with mo...

-

Hoffmann PP2-NCF - joining 3" wide cabinet door moulding with two Dovetail Keys

This video shows how to process typical cabinet door moulding ...

-

Hoffmann PP2-NCF programmable dovetail routing machine

The Hoffmann PP2-NCF automatic dovetail routing machine is a p...

-

Hoffmann PP2-NCF - joining 5 3/8" wide door casing with three Dovetail Keys

This video shows how to process large architectural door casin...

-

Hoffmann PP2-NCF - router head close up

This short video is a close-up of the left side router head, s...

-

Hoffmann PP2-NCF - joining 4" tall moulding with one Dovetail Key

This video shows how to process tall, thin material (4" tall b...

-

Hoffmann PP2-NCF with shutter z-frame, 2 Keys, single routing

Hoffmann PP2-NCF programmable dovetail routing machine Showing...

-

Hoffmann PP2-NCF with shutter z-frame, 3 Keys, double routing

Hoffmann PP2-NCF programmable dovetail routing machine Showing...