Product Description

Please click here to email us for a current freight quote – be sure to include your full address and whether you need optional services such as lift-gate service and/or residential delivery.

Hoffmann MU3-D Machine Overview:

Professional level, manually operated dovetail routing machine to rout a single dovetail keyway with each machining cycle.

Heavy cast aluminum construction with large, ergonomically shaped table surface, precision linear bearings, galvanized steel motor carriage with integrated motor fine adjustment and digital displays for routing height and routing location.

For Dovetail Key sizes W-0, W-1, W-2, W-3 (W-4 with optional larger motor)

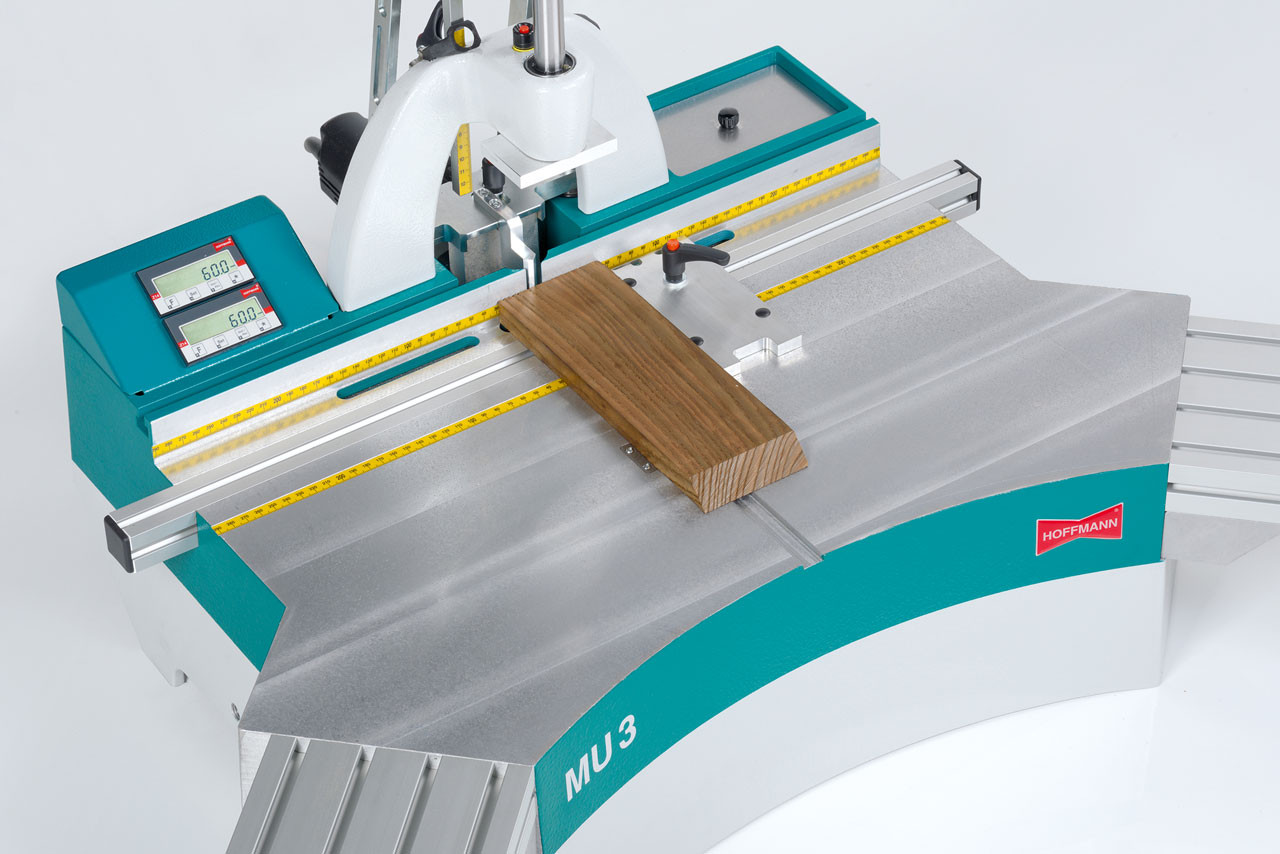

Hoffmann MU3-D - shown with optional table extensions

Highlights:

This manually operated dovetail routing machine does not require a compressed air supply. It can be equipped with the optional left and right hand extension tables, a helpful feature especially when processing longer parts.

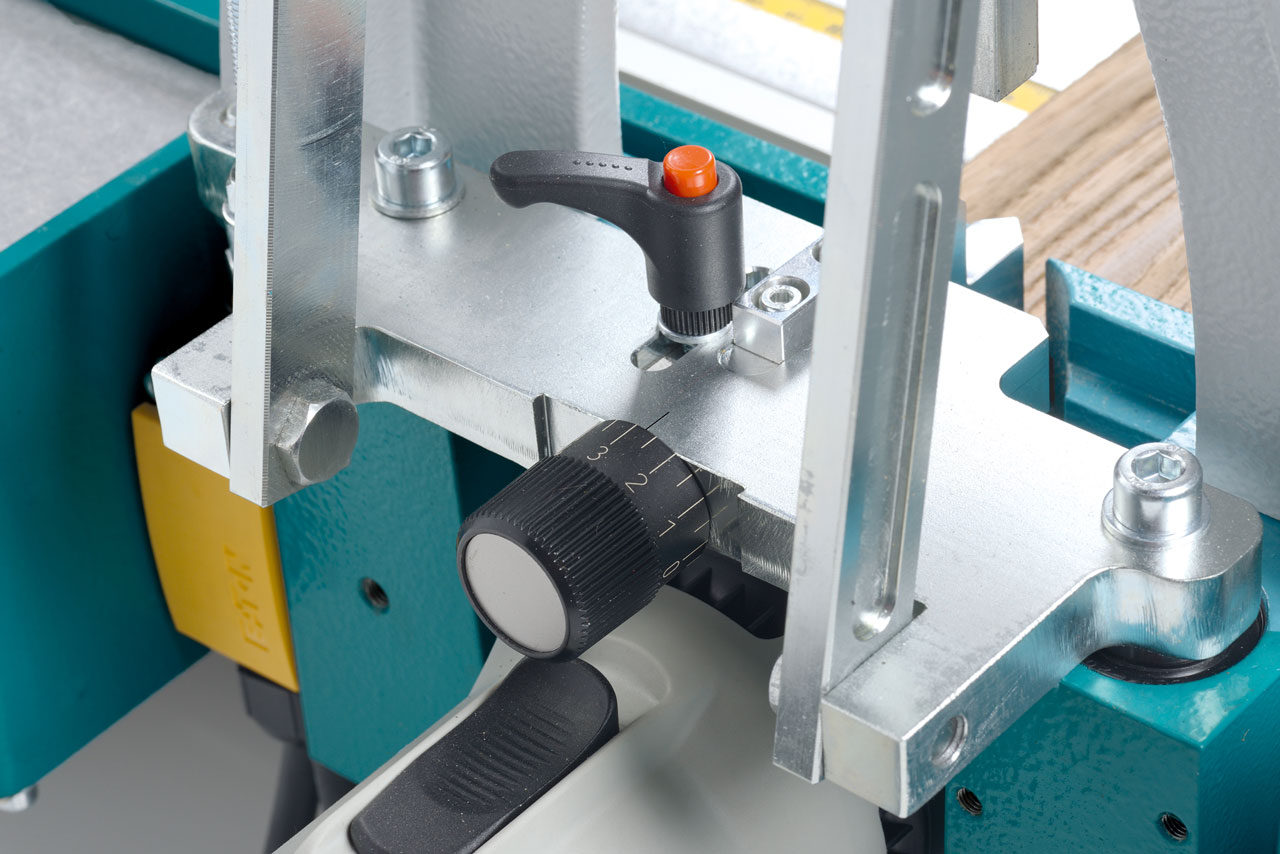

Motor fine adjustment and quick-release lever

Operation:

The keyway location is adjusted by positioning the guided center fence plate on the machine table;

the keyway length (routing height) is adjusted by setting a height-stop rod to the desired setting.

Both positions are shown on separate digital displays for accuracy and repeatability.

Digital Displays for keyway location and keyway length

Pulling the main lever downward starts the machining cycle:

> Padded hold-down plate secures work-piece and motor is switched on

> Continued pulling advances the router head until pre-set height is reached

> Releasing the lever returns the motor to its home position and shuts off motor

> Padded hold-down plate releases work-piece

With the operator controlling the speed of all machine movements, output is greatly depended on material flow, handling and operator performance.

On its backside, the large heavy-duty cast aluminum machine base has a 2" diameter dust collection port to connect a shop vacuum for dust free operation.

The supplied router bit is solid tungsten carbide, made to exacting specifications. Depending on the routing depth and the material to be routed, the useable cutter life is approx. 10,000 strokes, often times even more. Every machine is shipped with a tool kit and set-up jig, which allows a router bit change in only minutes.

Routing parts for a miter joint

Standard Features:

Hoffmann Dovetail Routing Machine, model MU 3-D, ready for operation, W-2 solid carbide router bit installed, standard 45 degree center fence plate, center line locator and square stop, motor fine adjustment, dual digital displays for keyway location and routing height, covered parts storage, toolkit and manual.

Motor 885 Watt motor with double front bearing

Motor speed 35,000 rpm at idle

Collet size 1/4”

Motor carriage guides 20mm diameter guide rods, precision ground

Digital Display dual liquid crystal display, 3/8” digit size, accurate to 0.004”

Operation manual– dual action design

Max. height routing 3 3/8” – 85mm / moulding 5 1/8” – 130mm

Dust collection port 2” – 50mm diameter

Installed router bit W-2, solid carbide

Available router bits W-0, W-1, W-2, W-3 (W-4 with optional larger motor)

Dimensions W/D/H 29 1/8” x 25 5/8” x 32 3/4” (without optional table extensions)

Weight 70.4 lbs.

Warranty:

One year on parts and workmanship. Complete Hoffmann Warranty Terms apply

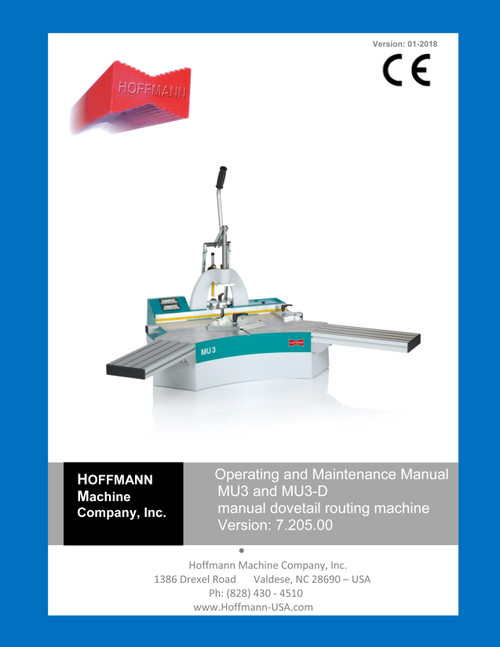

Click on images to download operating manual and related catalog

Product Videos

Videos Hide Videos Show Videos

-

Hoffmann USA MU3 and MU3 D manual dovetail routing machine

Hoffmann MU3 and MU3-D manual dovetail routing machine featuri...

-

Hoffmann USA MU3 D bit change, digital display calibration instructions

Video shows proper steps to change a router bit and to calibra...

-

Hoffmann MU3-PD review and real-life use - by Extreme Woodworker

This is an in-depth review and explanation of the Hoffmann MU3...