Product Description

Overview and Problems of wooden decking designs:

When building wooden decking to cover concrete or paved patios, walkways, pool surrounds, etc. the builder always has to contend with wood’s natural tendency to shrink in the drier winter months and to expand during the summer time.

These seasonal movements, combined with initial shrinking if not fully or properly dried wood is used, create tension and stress in every joint.

Many builders try in vain to combat wood movement by using more or longer nails or screws, and sometimes even adhesives. Additional layers of stain and “water-blockers” are used to protect the surface.

As soon as even a tiny crack develops in the finish, the wood absorbs and releases moisture again. Sooner or later, either the fastener or the wood itself will fail because no fastening method can completely eliminate natural movement.

Introduction of the FoX Decking Key:

We here at Hoffmann are very familiar with wood products and with the processes associated with seasonal changes in exterior wood products.

After extensive tests and a number of prototypes we have developed our FoX Decking Key.

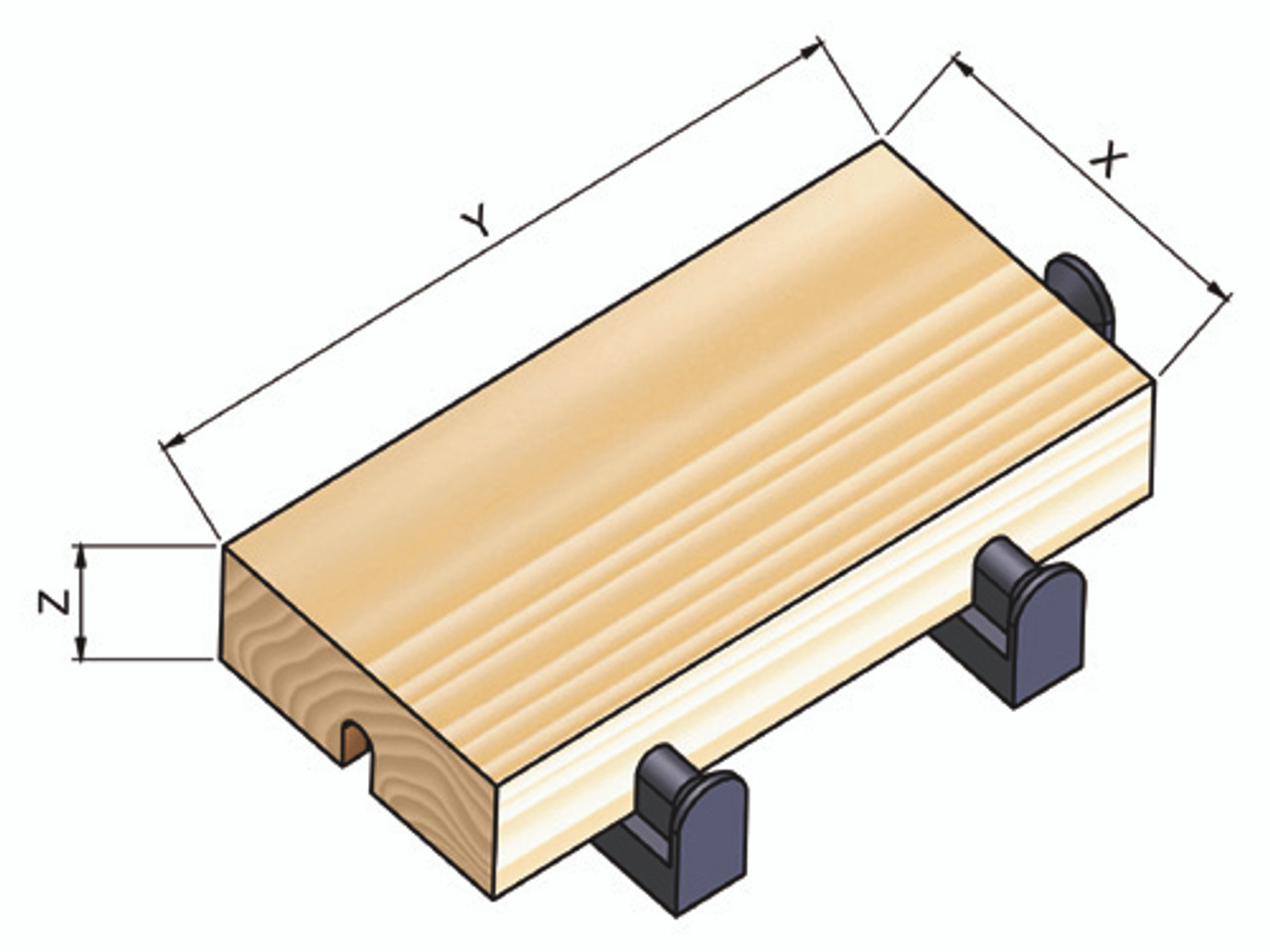

The FoX fasteners are made of natural rubber and are fully weatherproof, allowing the homeowner to clean his deck with a garden hose. The black color makes the Key “disappear” and no part of the fastener is seen from the surface, giving the deck a finished and professional appearance. The design of the Key assures a consistent gap between the boards of 5/32” = 4mm. This is generally seen as the proper space to provide thorough drying after a rainfall.

Decking on a concrete patio, wooden tiles on a balcony, sun rooms and conservatories, garden paths, interior wellness and spa areas and exterior pool surrounds are just a few of the possible applications for FoX Deck Keys.

Decking Material Options:

The Keys’ elasticity allows the wood components to expand and contract with seasonal humidity changes without splitting; a major benefit especially if pressure treated or not fully dried lumber is utilized.

A wide range of solid wood boards as well as wood composite material can be joined with FoX Keys.

Domestic species such as cedar, redwood and oak and tropical hardwoods like teak, Brazilian rosewood and ipe are all good choices if a solid wood deck is desired.

In addition, all types of composite decking boards can be utilized with this system.

The flooring keys are designed to hold the decking ½” above the floor surface to assure quick drying after rains, etc. In addition, this ½” space combined with the Key’s natural elasticity give the finished decking a pleasant feel when walked on.

Sub-floor requirements:

FoX Decking Keys are designed to assemble deck components with a flexible connection. Since the decking is not attached to the underlying structure it is essential that the subfloor is solid and rigid, e.g. concrete patio, pavers, black top (asphalt), flat field stone walkways, etc. The system should not be used on soft or unstable ground such as grass, sand, topsoil, etc.

Decking Layout Options:

The design options for decking shapes are almost endless, straight runs as well as angled and herring-bone patterns and even circular components can be joined on site with this system.

The builder decides what size material to use, either 5/4” solid wood boards or the equivalent composite decking in various widths. The quantity of FoX Decking Keys used per square foot of decking is depended upon the length and width of the individual components.

Machinery Choices:

FoX Decking Keys require matched keyways to be routed along the edges of the boards and we offer a range of professional quality dovetail routing machines for shop and on-site use.

Machine options include the MU-3 and MU-3D manual and the MU3-P and MU3-PD pneumatic bench-top machines, as well as the single-head PU-2 and the double-head PP-2 production freestanding machines. In addition, we offer length stop systems with multiple stops, automatic positioning systems and complete custom machines for high production levels.

(insert hyperlinks to the respective machine pages for each model )

Boards being routed for FoX Decking Keys on a Hoffmann PU-2 routing machine

Tooling:

The FoX router bits are made to the same high standard as our other dovetail router bits and the high-grade tungsten carbide assures long tool life, even when used with hardwoods or composite materials.

We offer matching 8mm collets for our dovetail routing machines and changing the bits takes only minutes. The minimum motor size for the FoX router bits is 750 watt (MU-2 model and up).

Tips & Tricks

Accurate positioning of the keyways is essential for a properly aligned finished deck. FoX Decking Keys are designed with a certain amount of flexibility to compensate minor off-sets when assembling the deck, but we recommend the use of either manual fence systems with pre-set flip-stops or automatic length stop systems for best performance.

The routing height is generally set at 11/16” (17.5 – 18mm) and should not be changed throughout the machining process to ensure a level floor.

The router bit feed rate is determined by the hardness and type of material being processed and can be adjusted on the pneumatic routing machines for best performance.

Typical material used for exterior decks:

Softwoods - larch, heart pine, cedar, cypress, redwood

Hardwood – white oak, locust, mahogany, ipè, teak and various tropical hardwoods

Composite – composite deck boards available from different manufacturers

Material thickness should range from 7/8” – 1 ¼”, width can range from 2”-6”

Gap width (board spacing)

The width of the gap between the boards can be adjusted to meet individual preferences.

For the recommended minimum gap of 5/32” (4mm) the router bit must extend 29/64” (11.5mm) from the back fence. For the maximum recommended gap of 1/4" (6.4mm), the bit should extend 13/32” (10.4mm). The routing machines can be adjusted to produce joints without any gaps, however because of the need to drain rain water and to allow the deck to dry out quickly, the minimum gap of 5/32” is recommended.

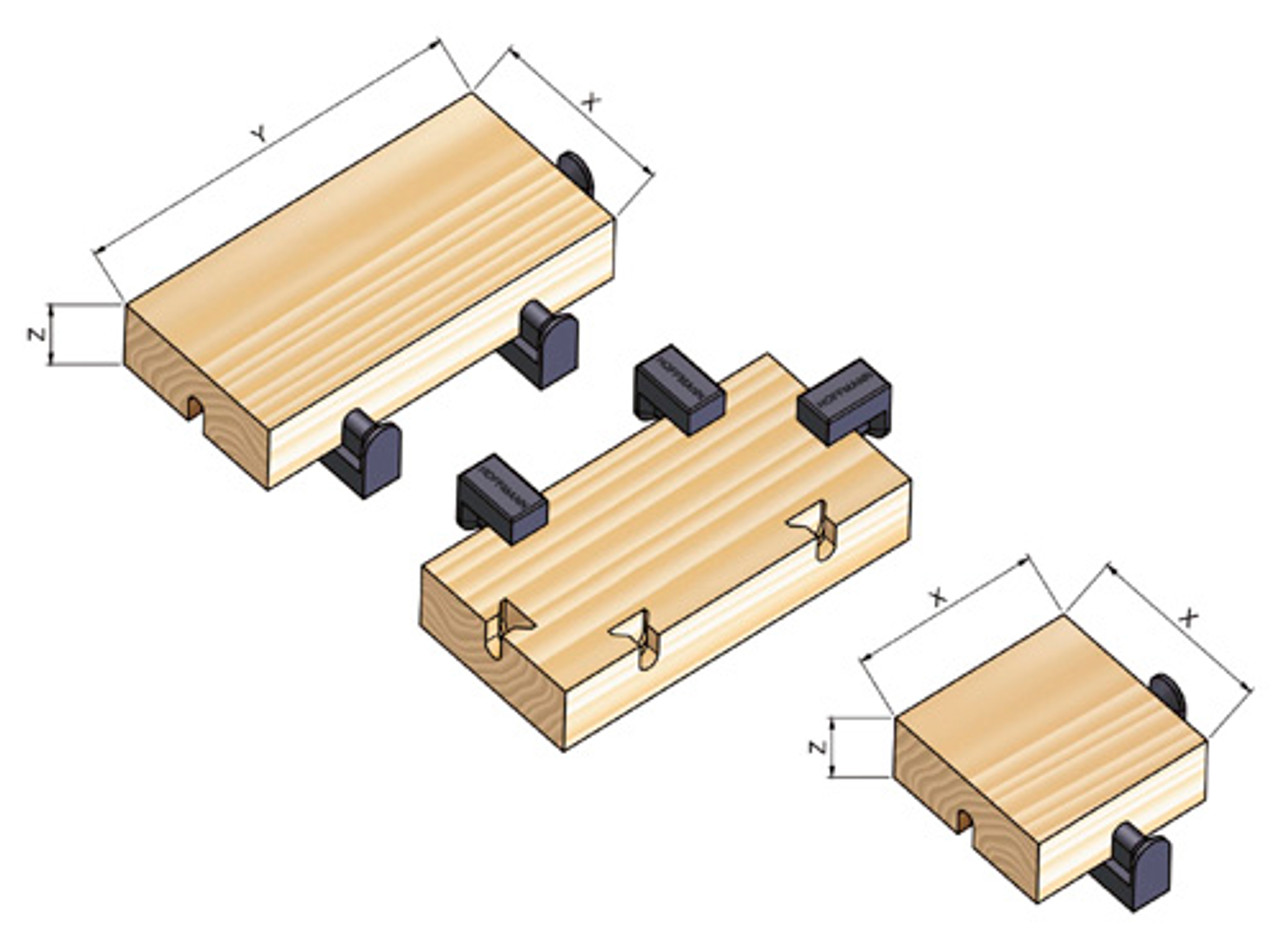

FoX Key Spacing

FoX Key spacing depends on width, thickness and stiffness of the decking material being used. We highly recommend producing a few sample boards with different spacing to assure desired results.

A good starting point is to place the first FoX Keys approx. 2” from the end of the boards and then every 8”-12”. Larger spacing results in fewer Keys needed but contractor should make sure all boards are properly supported to avoid sagging or too much downward flexing when stepped on.

Never exceed spacing recommended for similar deck boards attached to underlying joists and always follow local building codes. Due to the large number of different state and local codes and requirements, Hoffmann Machine Company is not responsible for adherence to or approval by state and local authorities for Fox Flooring Key System. We strongly recommend consulting local building department and/or local building inspector prior to commencing work.

Installation:

Hoffmann FoX, the innovative decking board connector, is installed without the need for any tools.

Inserted by hand in the pre-routed keyways, the natural rubber connectors are quickly set and the boards are connected by lightly pushing down with both hands.

Special Edge Keys are available for the perimeter boards to assure full support of the decking material along the edges.

Assembling the boards on site is simple and quick – much like a board game for children - and is accomplished in record time. No cutting, trimming or fitting is necessary – all pre-cut parts fit into place perfectly.

If the deck later requires cleaning or even refinishing, the boards can be disassembled with the same ease. Once the FoX Keys are removed, the boards can be cleaned and if necessary sanded and refinished before being reinstalled.

Damaged or discolored sections, for example boards beneath large flower pots, can be replaced quickly without the need to dismantle the whole floor.

Pricing:

FoX Decking Key, black, natural rubber

Part number qty per box price

W9700100 100 $ 34.50

W9700500 500 $134.00

W9701000 1000 $247.00

FoX Edge Key, black, natural rubber, to fill unused keyways along finished edges of flooring boards

W9710100 100 $22.00

W9710500 500 $86.00

W9711000 1000 $167.50

Carbide tipped router bit for FoX Keys, high-quality industrial carbide, 8.00mm shank

W2078000 1 $168.00